6-spindle machining of turbocharger rings

FM 3+X

Fixture with 2 × 3 workpiece arrangement and mechanical probe pins for checking the holes.

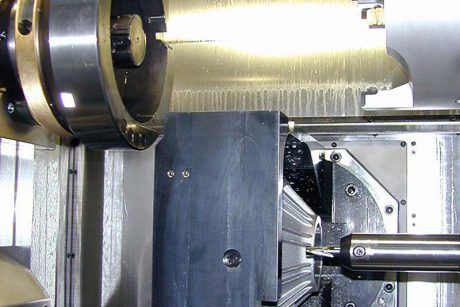

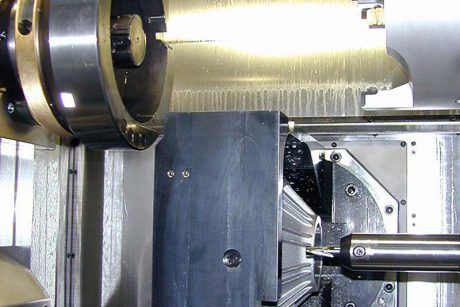

5-spindle machining of sleeves for the oil supply

FM 3+X

This configuration is equipped with additional NC rotary axes (5-axis) and enables highly productive manufacturing of two different types of work pieces.

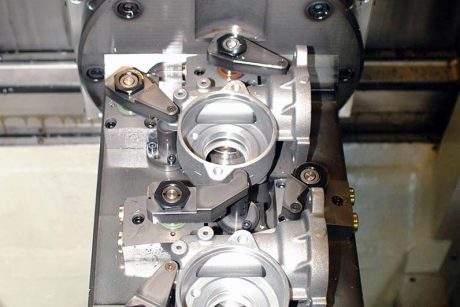

2-spindle machining of bearing housings

FM 4+X hd

Made from cast iron for passenger car engines with gang disk milling (10-fold).

Use of a special PCD bell-shape tool replaces an additional turning operation

FM 3+X

Optimal process design: Use of heavy HSK-100 spindles in combination with dynamic HSK 63 spindles.

Machining of pairs of suspension arms made of aluminum

FM 3+X

Left and right hand parts are made in one setup. The angular arrangement of work spindle enables processing of spatial angular operations without using a 5-axis.

Double machining of worm housings for steering

FM 3+X

The special arrangement of spindles allows a high-precision machining of the two main bores by avoidance of turover errors.