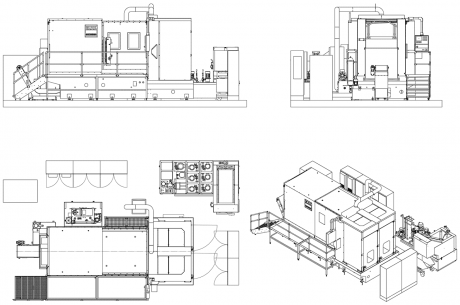

The machine is suitable for 6-spindle horizontal deep hole drilling of holes lying on bolt hole circles. The motor spindle working units are arranged at 6x 60° on a base plate and can be adjusted CNC-controlled to the required diameter.

The 3-jaw power chuck Ø1,250 is mounted on a movable rotary table unit. This ensures optimum accessibility for loading and unloading. The one-piece machine base was made of composite material and is optimally vibration-damping.

The holes with diameter 6-16 mm are completed in one working stroke. For spot drilling, the working units are equipped with hydraulically adjustable drill guide devices.

| Technical Details | ||

|---|---|---|

| Traverse path | X-axis (1-6) | 530 mm |

| Z-axis | 1400 mm | |

| drill ingot | 470 mm | |

| Feed rates | max. speed | 20 m/min |

| max. acceleration X / Z | 4 / 1.4 m/sec² | |

| max. feed force Z | 60000 N | |

| Main drive | max. capacity S1 / S6 | 13 / 16.9 kW |

| max. torque S1 / S6 | 49.7 / 64.6 Nm | |

| max. speed | 8000 rpm | |

| tool holder | HSK 63 mm | |

| Rotary table | diameter | 1250 mm |

| max. speed | 5 rpm | |

| Work piece | outer diameter | 780 – 1500 mm |

| section diameter | 510 – 1450 mm | |

| max. weight | 1500 kg | |

| Dimensions | space assignment | 10.4 x 6.2 x 4.3 m |

| total weight | 62000 kg | |