Agree to data transfer to YouTube and play video - Privacy policy

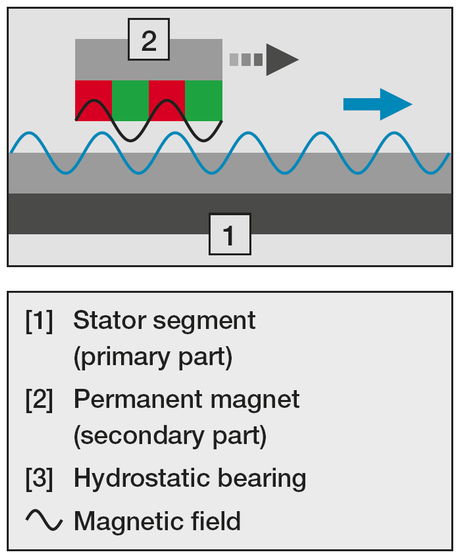

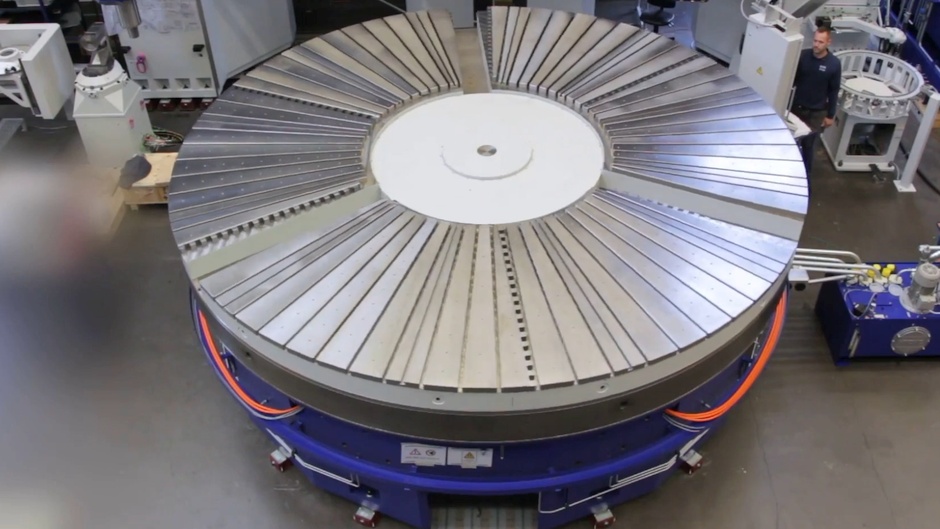

Agree to data transfer to YouTube and play video - Privacy policyThe table drive forms the centrepiece of a vertical multitasking machine and its performance in terms of machining precision and dynamics is decisive for the achievable workpiece qualities and economic efficiency of the machine. ELHA sets new standards in this respect with the patented SDD (Segment Direct Drive) rotary table direct drive with the following features:

- Outstanding dynamics: Significantly greater jerk factor (>100) than with conventional drives

- Extremely high positioning accuracy of <1″

- Excellent interpolation properties (transmit, double transmit)

- Optimum machining quality, as no influence from tooth meshing frequencies

- Very low noise emission

- Power, torque and speed are freely scalable using standard components

- Optimum concentricity due to elimination of drive radial forces and hydrostatic radial bearings

- No mechanical components subject to wear: long-term stable positioning and interpolation properties

- Operation still possible if individual motor segments fail

- Excellent thermo-symmetrical temperature control of the entire table base for minimised deformation

- Thermal losses can be utilised according to the heat pump principle

ELHA SDD turntable as retrofit set

Thanks to the modular properties of the VTM, the ELHA SDD rotary table can also be used as a stand-alone unit, for example as part of retrofits or overhauls of existing machines. This gives you the opportunity to utilise the outstanding precision, dynamic and technological properties of this rotary table in your existing machinery to achieve significant quality and productivity benefits.

Hydrostatic bearings and guideways

Rotary table radial bearing

Rotary table thrust bearing