Over the years, ELHA has evolved from a pure manufacturer of metal-cutting drilling and special-purpose machines to a provider of complete manufacturing process solutions including all the necessary services. Our starting point is your workpiece. From this we develop and realise, after the optimum, customised manufacturing solution - either on the basis of tried-and-tested machine concepts or according to individual requirements. machine concepts or according to individual, application-specific concepts. Our service portfolio therefore ranges from individual engineering services e.g. process development, machine and fixture design/construction through to complete turnkey solutions with automation including production support and the continuing aftercare with all typical associated services. This makes ELHA your competent, reliable partner when it comes to solutions with the highest quality and maximum performance.

ELHA process development overview

Discover here how ELHA turns your requirements into the realisation of your turnkey solution step by step. realisation of your turnkey solution. In addition, ELHA offers you on a service basis the possibility of realising individual service phases of process development, e.g. feasibility/process studies, rough and detailed concepts, profitability calculations and design services, process simulations and other services on request.

analyse

Requirements analysis

- Joint coordination of all technical, scheduling and commercial requirements and boundary conditions

- Detailed analysis with regard to the possibilities of economic, efficient implementation with a ELHA solution

Conception

- Development of proposed solutions based on a jointly agreed and prioritised catalogue of requirements

- Conceptual design based on a multi-stage concept model with different detailing phases and a structured, step-by-step process for developing the optimum production solution

- Coordinated scope with regard to the development of process fundamentals and associated machine technology approaches in each design phase

Validation

- Iterative specification and validation of the final solution concept

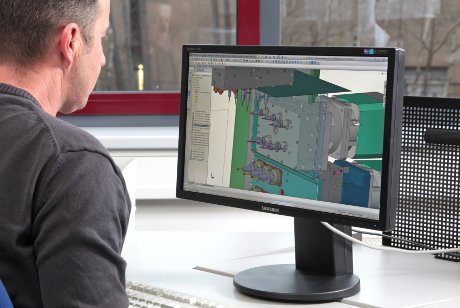

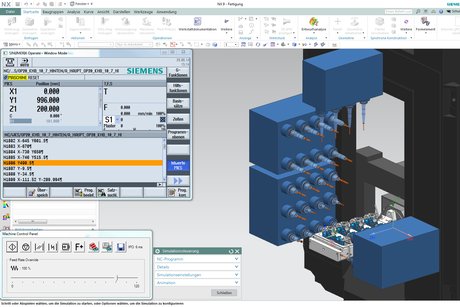

- Carrying out any necessary/requested trial/test machining, simulations and system analyses

Realisation

- Realisation engineering of process and machine technology incl. project management

- Setting up and running in the production system in the supplying plant

- Functional and process acceptance tests at the supplier plant

- On request, trial operation over an agreed period in the supplying plant

- Turnkey delivery and commissioning of the system at your plant

- Final acceptance including all agreed delivery, functional and process scopes at your plant

Production

- Competent training of operating and maintenance personnel

- Support during the production start-up phase / trial operation

- Project-specific support/counselling for your staff before, during and after completion of commissioning

- Effective ELHA service

- Short response time

- Efficient remote diagnostics

- Fast & uncomplicated processing

- High availability of spare and wear parts