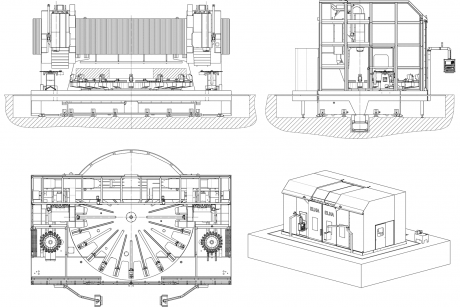

The machine is suitable for 2-spindle vertical drilling, turn-milling, boring, countersinking, reaming and threading operations on a bolt circle. The performance of the units is sufficient for drilling up to Ø60 mm into the solid and threading up to M56. Each machining unit is equipped with an HSK 100 geared drilling head. The tools can be changed automatically with the aid of extendable 20-position pick-up magazines. During machining, the tool magazines are protected from the work area by a safety door. The substructure/stand combination is divided into three sections and is made of composite material. A smooth rotary table plate with 12 manually operated clamping devices is integrated in the centre substructure. Despite its size, the machine is equipped with full panelling. Large sliding doors also enable easy crane loading.

Machine description

| Technical data | ||

|---|---|---|

| Travel distance | X-axis | 3,800 mm |

| Z-axis | 1,200 mm | |

| Feed rates | Max. maximum speed | 1.2 m/min |

| Max. feed force | 20.000 N | |

| Main drive | Max. power S1 / S6 | 46 / 55 kW |

| Max. torque | 586 / 2,344 Nm | |

| Max. speed | 3,250 rpm | |

| Rotary table | Diameter | 4,450 mm |

| Round table top | 6,100 mm | |

| Max. speed | 6 rpm | |

| Workpiece | Outer diameter | 2,300 - 5,500 mm |

| Inner diameter | 2,200 - 5,400 mm | |

| Max. height | 500 mm | |

| Max. weight | 10,000 kg | |

| Tool magazine | Tool places | 20 |

| Tool holder | HSK-A 100 | |

| Dimensions | Space requirements | 11.0 x 8.4 x 6.3 m |

| Total weight | 176,000 kg | |