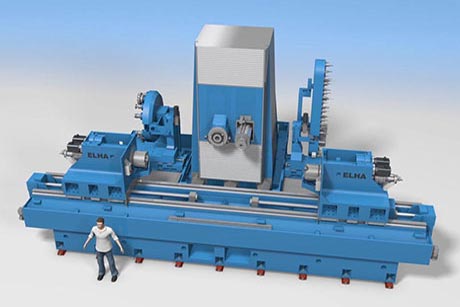

This machine is specially designed for machining pressure cylinders (max. Ø 800 mm; max. 2,000 mm long). The scope of machining includes turn-milling of the lateral surface, channel milling and drilling. The machine is characterised in particular by high accuracy, high thermal stability and excellent damping properties.

The heavy-duty HSK 160 main spindle unit (150 kW) is primarily used for turn-milling and channel milling operations. This unit is equipped with a 14-disc magazine. The dynamic HSK 100 ram unit (50 kW) is mainly used for drilling operations. This unit is equipped with a 40-slot oval pusher carriage magazine. The tools are changed using a double gripper.

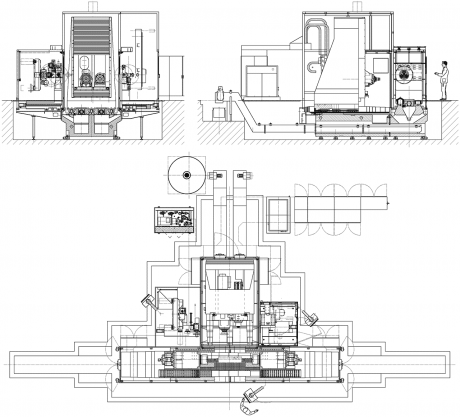

The centring and clamping units (X1 and X2 axes) can be moved separately in loading and unloading mode. The X axes are electronically coupled during machining. The rotary axes (A1 and A2) are driven on both sides and are also electronically coupled.

| Technical data | ||

|---|---|---|

| Travel distance | X1 / X2 axis | 2,710 / 2,670 mm |

| Y-axis | 800 mm | |

| Z1 / Z2 axis | 1,050 / 500 mm | |

| U1 / U2 axis (WZW) | 1,150 / 900 mm | |

| Feed rates | Max. speed (Z2) | 30 (40) m/min |

| Max. acceleration (Z2) | 2.5 (6) m/sec² | |

| Max. feed force (Z2) | 20 (12) kN | |

| Main drive 1 | Max. power S1 | 150 kW |

| Nominal torque 1 / 2 | 6,000 / 2,295 Nm | |

| Max. speed | 1,600 rpm | |

| Main drive 2 | Max. power S1 | 50 kW |

| Rated torque | 300 Nm | |

| Max. speed | 7,260 rpm | |

| Rotary axes | Max. torque | 9,000 Nm |

| Max. speed | 20 rpm | |

| Clamping range | 52-220 mm | |

| Max. workpiece weight | 1,500 kg | |

| Dimensions | Space requirements | 12.1 x 10.3 x 6.2 m |

| Total weight | 130,000 kg | |

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy