This page has been translated automatically.

Choose from a wide range of different peripheral equipment options and optimise the FM SMART to suit your needs.

|

|

|

| SMART | Series 1 | Series 2 |

|---|---|---|

| COOLING LUBRICATION | ||

| Coolant system, water based | ○ | ○ |

| Coolant system, oil based | ○ | ○ |

| High-pressure pump size I or II | ○ | ○ |

| Duplex filter | ○ | ○ |

| Chip conveyor | ○ | ○ |

| Flushing gun | ○ | ○ |

| MECHANICS | ||

| Exhausting unit | ○ | ○ |

| Fixture change support unit | ○ | ○ |

| Preparation for additional unit | X | ○ |

| Cone cleaning | ○ | ○ |

| High Dynamic package | X | ○ |

| AUTOMATION | ||

| Level I | ⬤ | ⬤ |

| Level II (with conveyor) | ○ | ○ |

| ELECTRIC / CNC | ||

| Remote diagnosis | ○ | ○ |

| Load monitoring | ○ | ○ |

| Shop Mill | ○ | ○ |

| Virtual machine | ○ | ○ |

| Measuring probe | ○ | ○ |

| PROCESS ENGINEERING | ||

| Geometry acceptance | ○ | ○ |

| Tool scheme | ○ | ○ |

| NC programming | ○ | ○ |

| Construction of clamping device | ○ | ○ |

| SERVICES | ||

| Simulation | ○ | ○ |

| Cycle time calculation | ○ | ○ |

| Transport | ○ | ○ |

| Reassembly and commissioning | ○ | ○ |

| Production support | ○ | ○ |

| EDUCATION / TRAINING | ||

| Mechanics / hydraulics | ○ | ○ |

| Electrics / Electronics | ○ | ○ |

| Operation / Programming | ○ | ○ |

| Production of clamping device | ○ | ○ |

| ⬤ = standard, ○ = option, X = not possible | ||

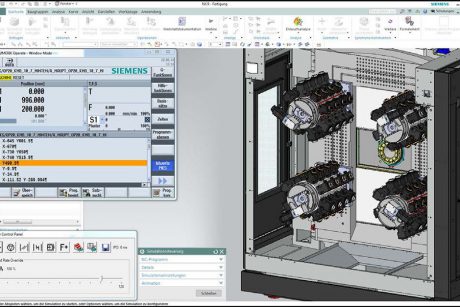

Virtual machine

With the virtual machine, ELHA offers an extremely productive simulation tool that links the real properties of the machine with the process data from the customer's CAD/CAM environment. This opens up the possibility of very precise machining studies and process simulations including collision checks in 3D. This minimises the time required for feasibility/economic tests and set-up processes.

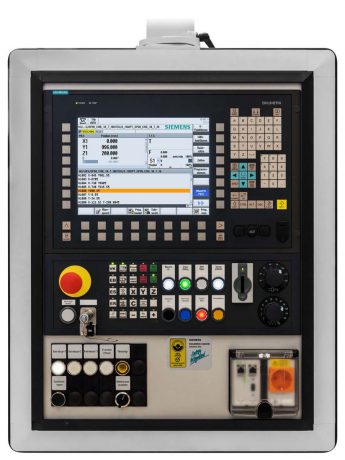

SIEMENS 840D sl control unit

The standard in highly productive environments. Equipped with all the parameters required for processing.