Always more productive, always more efficient... and better than the competition! And quality anyway... These are the demands our customers place on us. In our endeavours to master these challenges, we have developed and implemented many machine technology innovations in the course of our many years of work in the field of of machining process solutions, we have also developed many machine technology innovations, which often provide the decisive advantage for our customers and thus the deciding factor in favour of a ELHA solution. Get to know some of these innovations and key technologies here and convince yourself of the associated innovative strength that characterises ELHA.

Multi-spindle technology

The attribute "highly productive" has been inextricably linked with the name ELHA for decades! Then as now, the use of multi-spindle drilling, and milling machining in countless versions is an important key to this! Be it for the "one shot" insertion of complex drilling patterns or hundreds of holes in series format or the simultaneous multi-spindle machining of several components. In a wide variety of machine and We have reliably implemented this technology in a wide variety of machine and system concepts, such as linear, transfer or rotary transfer machines. The latest innovations in this area include the spindle fine adjustment option in multi-spindle heads, which enables µm-precise, manual 2-axis position and angle adjustment of the spindle axis.

Flyer fine spindle adjustment

ELHA SRR - The Drum Type Turret

Productivity and flexibility are no longer mutually exclusive. In order to realise this goal in the area of highly productive transfer centre technology in the ELHA production modules, we have developed the drum type turret. This not only enables powerful 2-4 spindle machining with directly with directly driven tools, but also provides the required tool capacity and convenient tool exchangeability, as with the machining centre. and eliminates non-productive times caused by tool changes in practical operation thanks to lightning-fast indexing.

Spindle turret info

The h-technology

In our endeavours to significantly increase machining stability and vibration damping in the ELHA production module, our path led us to the development and use of the patented h technology. This is a large, hydrostatically guided quill that performs both the linear and rotary movement of the workpiece carrier. rotational movement of the workpiece carrier. In combination with a highly dynamic double drive in the longitudinal and torque drive in the rotative direction, this technology maximises productivity and machining accuracy. The h-technology technology was also used as a spindle quill in other special machines where maximum stability and accuracy were required, for the high-performance machining of titanium components, for example.

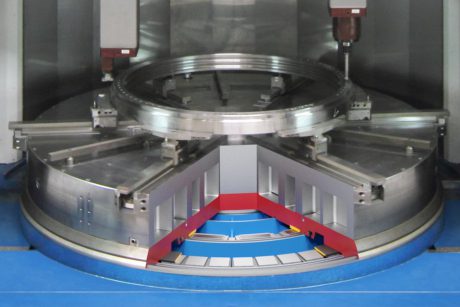

ELHA SDD - Segment Direct Drive

Non-contact linear motor technology has long been established in highly dynamic precision machining in machining centres. ELHA has taken this technology a step further and implemented it in the form of a patented rotary table drive. The result is the world's best rotary and indexing tables in the 2-8 m diameter range in terms of positioning accuracy (±1") and dynamics. This makes the ELHA SDD the first choice for high-precision and dynamic interpolation machining and for highly productive indexing machining of hole patterns, for example in slewing bearings and flanges.

Info Direct Drive segment Agree to data transfer to YouTube and play video - Privacy policy

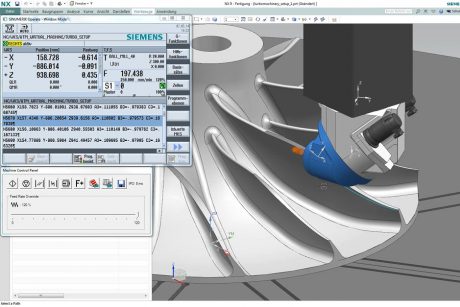

Agree to data transfer to YouTube and play video - Privacy policyVirtual machine

With the virtual machine, ELHA offers an extremely productive simulation tool that links the real properties of the machine with the process data from the customer's CAD/CAM environment. This opens up the possibility of very precise machining studies and process simulations including collision checks in 3D. This minimises the time required for feasibility/economic tests and set-up processes.

BSFZ

Since June 2023, we have been allowed to bear the official seal of the Federal Ministry after our SRM development concept received a positive decision from the Certification Centre for Research Grants (BSFZ).

The award of the exclusive BSFZ seal confirms that we as a company are eligible for funding and are actively involved in research and development. It is an award for our innovative expertise and shows that we continuously strive for advanced solutions to fulfil our customers' requirements and drive the industry forward.

We are proud to carry this prestigious seal and will continue to strive to drive our research and development activities to deliver innovative solutions that delight our customers.

Find out more about our developments and contact us today to find out how we can help you achieve your production and technology goals.