High-speed cutting of large ship propellers: mastering challenges with parallel kinematics modules

Current challenges in the high-speed milling of large ship propellers

The machining of large ship propellers presents several challenges. Due to the size of these components, advanced machines are required that enable fast, reliable and precise machining. Important aspects here are:

- Processing time: High chip removal rates are crucial for meeting production deadlines.

- Surface quality: A high-quality surface finish is crucial for the optimum performance of a propeller. Achieving excellent surface quality during the machining process can significantly reduce operating costs as additional finishing steps, such as extended polishing time, can be minimised.

How parallel kinematics modules (PKM) master the high-speed machining of large castings

Thanks to its unique properties, the PKM has proven its efficiency in high-speed milling:

- Fast and precise processing: The combination of a rigid and lightweight structure ensures constant performance even at high feed rates, which reduces machining time and increases reliability.

- Large workspace: The PKM is designed for large components and offers sufficient space for massive components.

- Compact design: The design minimises the initial investment in foundations and offers flexibility when adapting to existing systems. In addition, the lightweight modular structure results in significantly lower energy consumption compared to conventional solutions.

- One-time fixation: The large working volume and the reach of the machine enable a complete side of the propeller to be processed without reclamping.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyOutstanding surface quality with parallel kinematics modules

The PKM uses advanced techniques to achieve exceptional surfaces:

- Process simulation: Precise path and tool planning thanks to the digital twin

- 5-axis movement: The ability of the PKM to move freely around the propeller, without singularities, ensures constant contour accuracy.

- Fast tool realignment: 5 times faster tool realignment thanks to high acceleration and parallel kinematics.

- Calibration and compensation: Increases the accuracy of the machine and compensates for external influences.

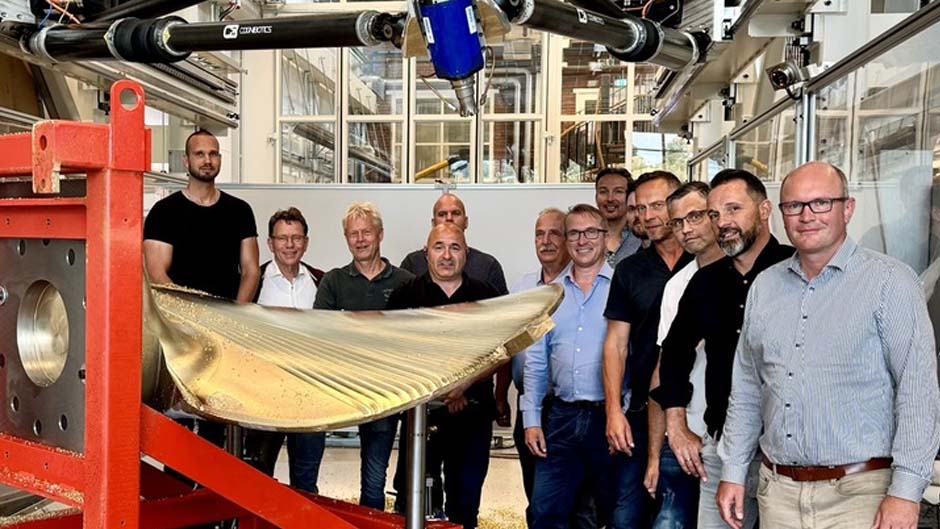

Joint demonstration and process validation by ELHA-MASCHINENBAU and Cognibotics in Lund, Sweden, together with the propeller manufacturer MMG and the tool manufacturer Pokolm.

Klaus Saffian - Production Manager at MMG:

"As a manufacturer of large ship propellers, we faced numerous challenges with the cost of high-speed machining of our large components.

That is why we have tested the SigmaTau ST 3000 robot and are extremely impressed with its performance. The ST 3000 processes castings of different sizes with remarkable efficiency, and the competitive processing times help us to fulfil our production requirements. The exceptional surface quality reduces subsequent polishing steps, making our process faster and more cost-effective."

General information on metalworking

Fast

Spindle speed up to 80,000 rpm, feed speed up to 50 m/min.

Fast tool deflection thanks to the jerky and parallel kinematics.

Precise

High contour accuracy and high repeatability.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyVisit MMG:

Click here for the website

Find out more about the PKM:

Click here to return to the overview page

Please contact us:

Do you have questions about the PKM?