Since the early days of machining industrial mass products, machining technology has been constantly developed and improved. Modern component materials and the constant optimisation of tool technologies have led to a dramatic reduction in machining times.

Non-productive times have also been continuously reduced. However, this development has not yet kept pace with the increase in productivity of the machining processes, which has a negative impact on the productivity of the overall process. Particularly in machining operations with a large number of different tools and short process times, such as drilling and thread machining, productivity suffers considerably from unproductive non-productive times, e.g. due to tool and/or pallet changes.

This was one of the decisive reasons for ELHA to question all previous concepts. The result of these efforts was the development and extremely successful market launch of an ingenious machining concept that has revolutionised the machining production of mass-produced components!

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyConventional machining

on a machining center

- Tool spindle changes the tools according to the process

- Tool spindle moves from/to the workpiece

Ideal concept for:

- Small and medium quantities

- Large number of different workpieces and fixtures

Paradigm shift

with an FM production module

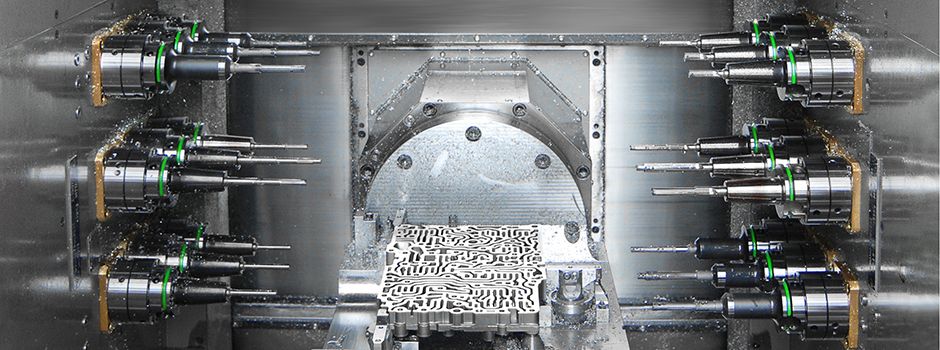

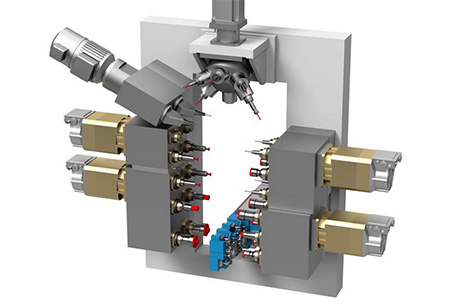

- All required tools are arranged in a defined position in the workspace

- Each tool has an optimised clamping and drive system in corresponding multi-spindle heads or turrets

- The worktable with fixture and workpiece(s) moves from tool to tool, resulting in the shortest chip-to-chip times

- No tool change in the process; no inaccuracies due to tool change

- Single/multiple clamping or single/multi-spindle machining possible (depending on application)

Ideal concept for:

- Mass production from approx. 100,000 of the same/similar parts per year

- Small and medium-sized workpieces

- Limited number of different workpiece types

- Moderate number of different tools and clamping positions

- Ideal for light metals, (stainless) steels as well as cast and forged alloys