This page has been translated automatically.

The machine is suitable for 1- or 2-spindle vertical drilling, boring, countersinking, taper reaming and tapping of holes arranged on bolt circles. The power of the two ram units is designed for solid drilling up to Ø35 mm and tapping up to M24.

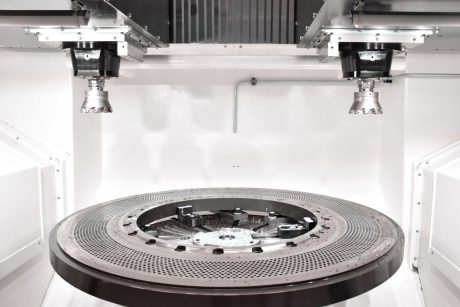

The one-piece machine base with integrated crossbeam is made of a vibration-damping composite material. The substructure surfaces are designed at an angle to the chip conveyor. A 3-jaw power chuck is integrated into the Ø820 mm rotary table.

Two fixed pick-up tool changers provide space for up to 16 tools. The machine is equipped with a fully enclosed work area. Two manually operated sliding doors are opened for crane loading.

Machine description| Technical data | ||

|---|---|---|

| Travel distance | X-axis | 925 mm |

| Z-axis | 550 mm | |

| Feed rates | Max. maximum speed | 30 m/min |

| Max. acceleration X / Z | 2.5 / 3.0 m/sec² | |

| Max. feed force X / Z | 3.000 / 8.000 N | |

| Main drive | Max. power S1 / S6 | 20 / 30 kW |

| Max. torque S1 / S6 | 95 / 143 Nm | |

| Max. speed | 6,800 rpm | |

| Rotary table | Diameter | 820 mm |

| Max. speed | 5 rpm | |

| Workpiece | Outer diameter | 500 - 1,500 mm |

| Inner diameter | 180 - 780 mm | |

| Max. height | 250 mm | |

| Max. weight | 1,500 kg | |

| Tool magazine | Tool places | 16 |

| Tool holder | HSK-A 63 | |

| Tool length | 300 mm | |

| Dimensions | Space requirements | 5.8 x 3.7 x 3.6 m |

| Total weight | 28,000 kg | |