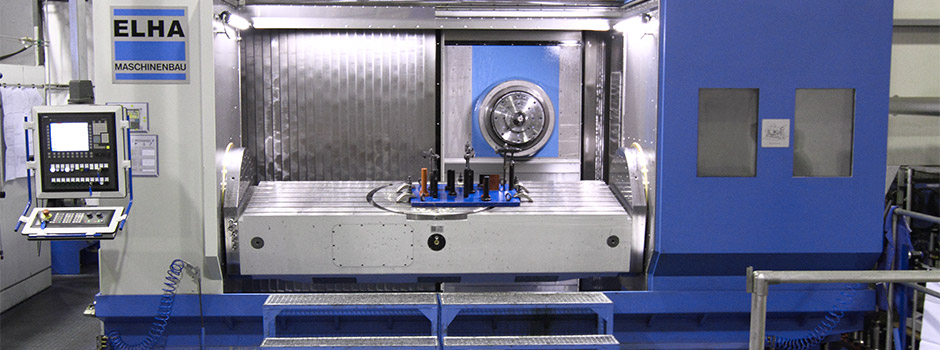

This new 5-axis special horizontal machining centre represents a new generation of ultra-stable and powerful machines with outstanding properties for machining the most difficult-to-cut materials such as titanium, Inconel and other materials and alloys used primarily in the aerospace sector.

The hydrostatically guided Z-axis ram with an increased diameter of 450 mm, already familiar from the large FM 4+X hd module, is used here. The excellent damping and stability of this axis and the powerful milling drive with a 37 kW HSK-A 125 milling spindle, combined with the composite base machine, ensure record-breaking cutting volumes, precision and surface finishes! Thanks to the 3000 mm long and 1000 mm wide swivelling rotary table with integrated rotary table of 1000 mm, a wide range of workpieces can be produced, from chassis parts to large structural components, not only in the aerospace sector.

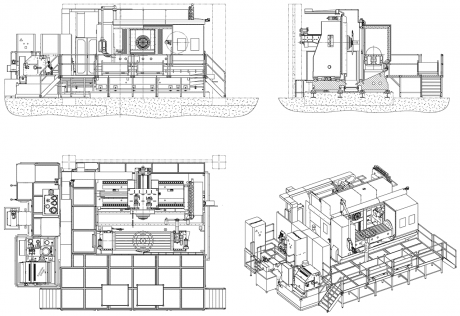

Machine description

| Technical data | ||

|---|---|---|

| Travel distance | X-axis | 2,500 mm |

| Y-axis | 1,150 mm | |

| Z-axis | 1,000 mm | |

| Feed rates | Max. speed X / Y / Z | 30 / 30 / 48 m/min |

| Max. acceleration X / Y / Z | 1.3 / 3 / 4 m/sec² | |

| Max. feed force | 20.000 N | |

| Main drive | Max. power S1 | 37.7 kW |

| Max. torque S1 (1 / 2) | 1,425 / 285 Nm | |

| Max. speed | 4,000 rpm | |

| Ram diameter | 450 mm | |

| Bridge / Rotary table | Swivel bridge | 3,000 x 1,000 mm |

| Reversible clamp diameter | 800 mm | |

| Table diameter | 1,000 mm | |

| Tool magazine | Tool places | 60 |

| Tool holder | HSK-A 125 | |

| Tool length / diameter | 500 / ∅250 mm | |

| Dimensions | Space requirements | 11.8 x 7.9 x 4.8 m |

| Total weight | 70,000 kg | |