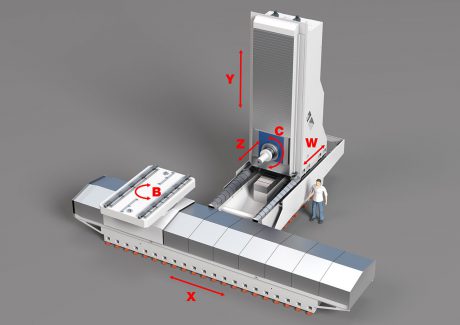

This machine marks a new milestone for large horizontal machining centres in terms of dimensions, stability and flexibility. The SMX 5239 was conceptually developed for the machining of machine tool frame components. The basic structure consists of a solid, movable column for secondary positioning in which a dynamic 2-axis unit is integrated to perform the main movements during machining. A rotating, hydrostatically mounted round ram with a generous 450 mm diameter is also installed in this unit, which is designed to accommodate attachment units for a wide range of operations.

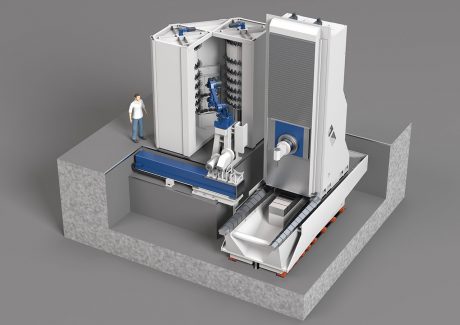

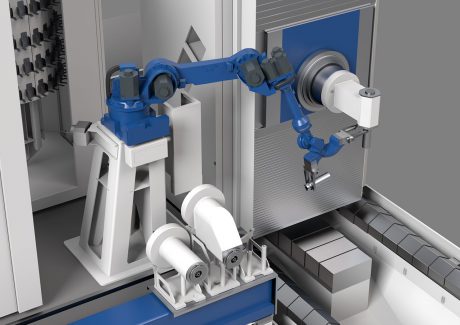

The ram unit is equipped with a tool spindle drive with a 2-stage gearbox for high speeds/torques. A Ø2000 mm rotary-sliding table is arranged transversely to the work unit, on which pallets measuring 4500 x 2000 can be clamped. Another highlight is the possibility of unmanned production by using an automatic pallet changing system with 3 pallets, which can be changed one after the other. For high flexibility and the shortest possible set-up times, a large magazine for storing 360 HSK tools is located at the side, which enables automatic tool changing by robot.

Machine description| Technical data | ||

|---|---|---|

| Travel distance | X-axis (rotary table) | 5600 mm |

| Y-axis (cross slide) | 3500 mm | |

| Z-axis (round ram) | 1000 mm | |

| W-axis (upright) | 2650 mm | |

| Pallet changer | 1250 mm | |

| Attachment head changer | 2300 mm | |

| Positioning accuracy | 0.02 / 4500 mm | |

| Main drive | Max. power S1 | 37.7 kW |

| GS1: Max. torque S1 / S6 | 1500 / 1920 Nm | |

| GS2: Max. torque S1 / S6 | 300 / 384 Nm | |

| Max speed GS1 / GS2 / S6 | 1300 / 6500 min-1 | |

| Rotary table / pallet | Rotary table diameter | 2000 mm |

| Pallet size | 4500 x 2000 mm | |

| Workpiece weight | 18 t | |

| Pallet changer | 3 | |

| Head changer / tool storage | Attachment heads | 3 |

| Tool places | 360 | |

| Tool holder | HSK-A 100 | |

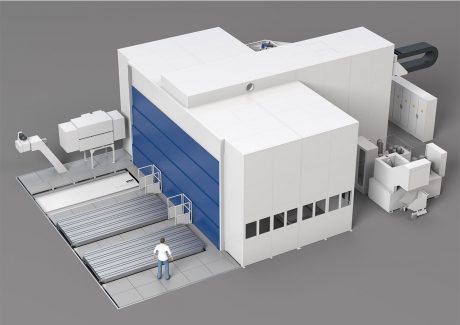

| Dimensions | Space requirements | 18,5×11,8×5,6 m |

| Total weight | 180 t | |