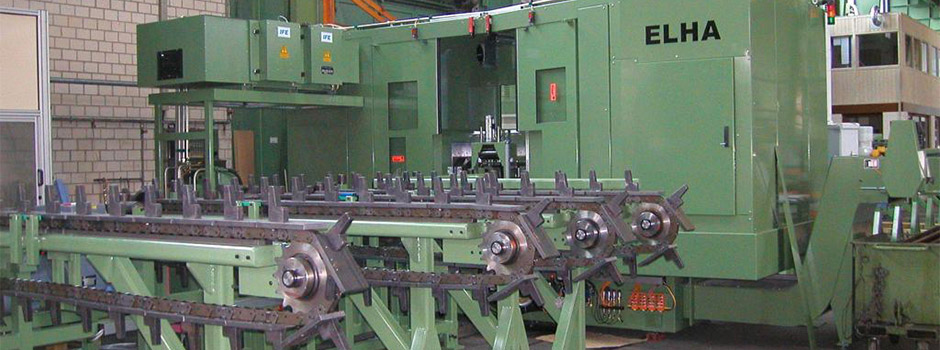

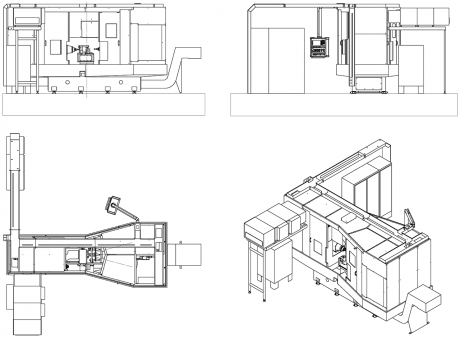

This machine is suitable for drilling and double-sided chamfering of rail profiles in various shapes and dimensions. Drilling is carried out with a 2-axis unit that can be swivelled by ±15°. This unit is equipped with an additional 6-position tool changer. The rear chamfering of the bores is carried out with a non-swivelling 2-axis unit on the opposite side.

The machine was equipped with patented software in order to be able to produce uniform chamfers on both sides despite large tolerances on the workpiece. This programme enables chamfers with a tolerance of ±0.3 mm.

The feed magazine next to the machine can hold up to 10 rails. A feed roller conveyor transports raw part rails with a length of up to 15 metres into the machine. The machine is equipped with a CNC-controlled rail positioning device for precise positioning of the rails. After processing, the finished rails are picked up by a discharge magazine.

| Technical data | ||

|---|---|---|

| Travel distance | Y-axes | 100 mm |

| Z-axes | 320 mm | |

| Rail transport | 18,000 mm | |

| Tool magazine | 450 mm | |

| Swivelling range | ±15° | |

| Feed rates | Max. maximum speed | 30 m/min |

| Rail transport | 10 m/min | |

| Main drive | Max. power S1 / S6 | 20 / 25 kW |

| Max. speed | 4,000 rpm | |

| Tool holder | SK 50 | |

| Tool magazine | Tool places | 6 |

| Max. tool length | 230 mm | |

| Max. tool diameter | 60 mm | |

| Parts magazine | Workpiece length | 1,000-15,000 mm |

| Overlay width | 2,500 mm | |

| Conveying speed | 6 m/min | |

| Dimensions | Space requirements | 37.2 x 6.7 x 3.0 m |

| Total weight | 37,500 kg | |