This page has been translated automatically.

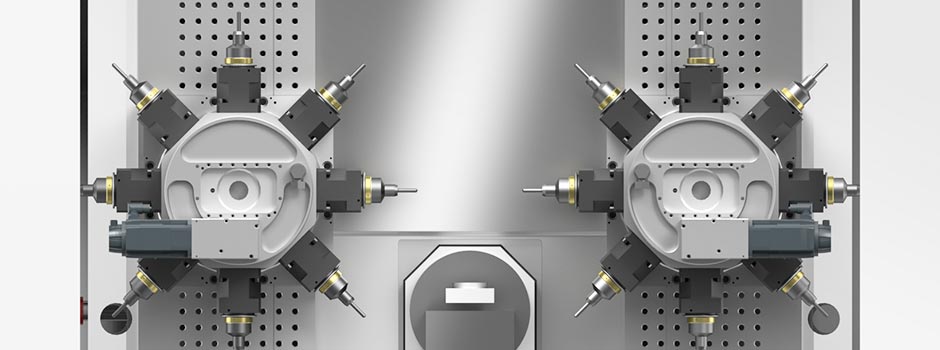

Highly productive, flexible multi-spindle machining in a new design

ELHA-MASCHINENBAU has been known for many years as the market leader in highly productive transfer centres, primarily in the field of large-scale automotive production. Over 350 units installed and run-in with processes document the success of this concept.

With the FM SMART series, ELHA offers unprecedented flexibility in multi-spindle machining for transfer centres and thus represents an alternative to conventional machining centres.

Ideal concept for:

- Medium to high quantities

- Small and medium-sized workpieces

- Quickest possible retooling

- Ideal for light metals, (stainless) steels as well as cast and forged alloys

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyWorkpiece examples

Planet carrier

- Steel

- Complete machining in one clamping position

- 4 workpieces at the same time

Joint piece

- GGG 70

- Complete machining in one clamping position

- 2 workpieces at the same time

Wheel flange

- Grey cast iron

- Partial machining in one clamping position

- 2 workpieces at the same time

Pump housing

- Die-cast aluminium

- Complete machining in one clamping position

- 3 workpieces at the same time

Turbocharger center housing

- Cast steel

- Partial machining in one clamping position

- 3 workpieces at the same time

Cylinder head

- Forged steel

- Complete machining in two clamping positions

- 4 workpieces at the same time