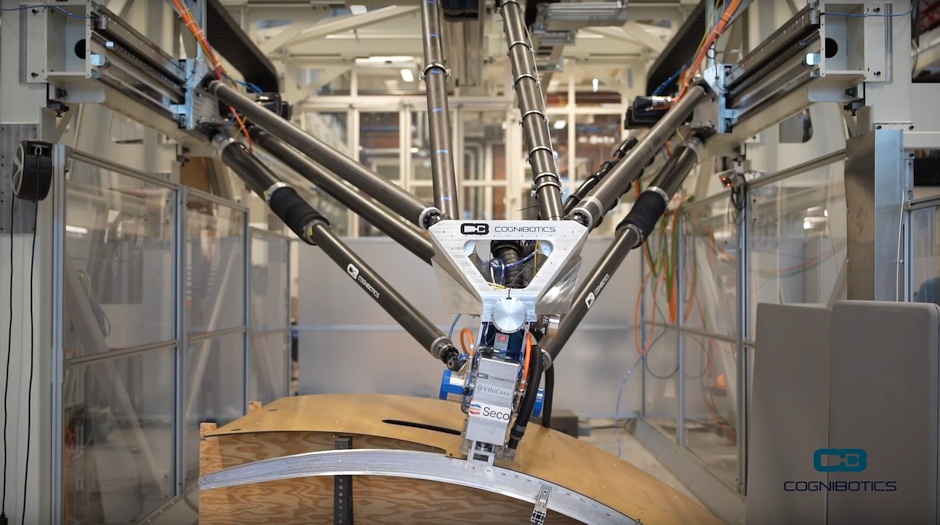

In high-volume production, where drilling through different stacks of material is routine, the PKM provides the precision and rigidity required for a safe, efficient process. The ability to use the same spindle for both drilling and trimming within the same set-up increases operational efficiency and reduces downtime.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyParallel kinematics module for vibratory drilling

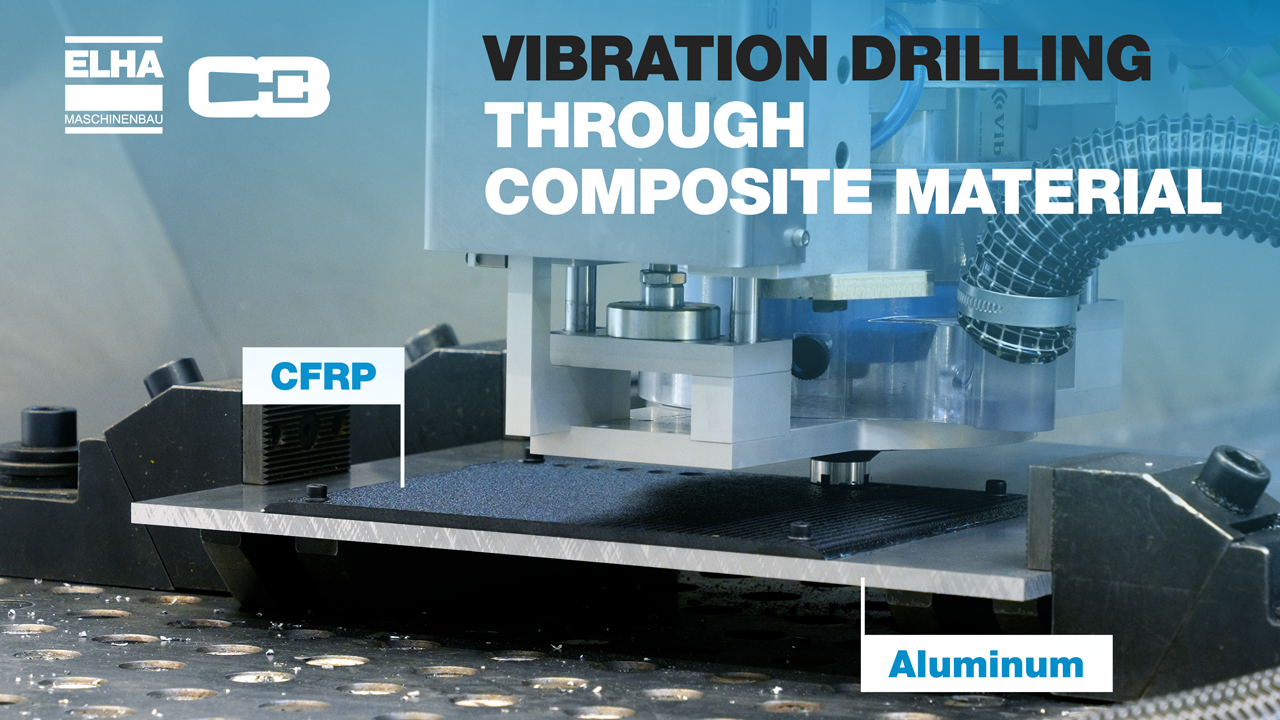

The PKM offers transformative solutions to the challenges of vibratory drilling in large-scale manufacturing projects, such as those found in aerospace construction. The PKM is characterised by the following features in this demanding environment:

● Modular designThe modular design of the PKM allows easy configuration in different orientations and makes it extremely adaptable to different production requirements and workspaces.

● Control & software: The complete integration of the spindle control with the machine control ensures precise operation and functionality, increasing the efficiency and quality of drilling operations.

● Seamless integration: The PKM features a simplified spindle end effector setup made possible by its fully parallel robot technology. This seamless integration allows for easy adaptation to different drilling applications without the need for extensive reconfiguration.

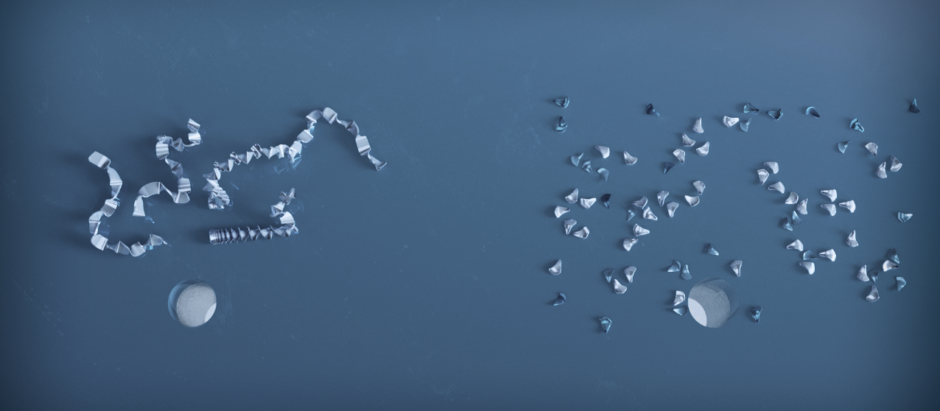

● Vibration technology: The PKM features advanced vibration technology that supports the drilling process. This innovative approach ensures that the chips are broken down into small fragments, reducing the risk of tangles that can affect the quality of the hole and the efficiency of the drilling process.

PKM with Vibicore spindle and Seco cutting tools

The PKM, equipped with the VibiCore vibration spindle and Seco cutting tools, offers the operator enhanced control over the drilling process. In tests, this spindle has demonstrated optimised NC-controlled drilling patterns that are tailored to each material layer and produce precise and clean holes.

Simulation of the PKM drilling process for rivet holes for aircraft wings

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyA controlled pressure foot helps to stabilise the material layers during drilling trials, reducing the risk of detachment and enabling efficient removal of sharp chips, helping to maintain the cleanliness and integrity of the workpiece. The pressure foot also features an integrated linear encoder that enables precise control of axial depth and countersink - results that promise consistently high quality holes.

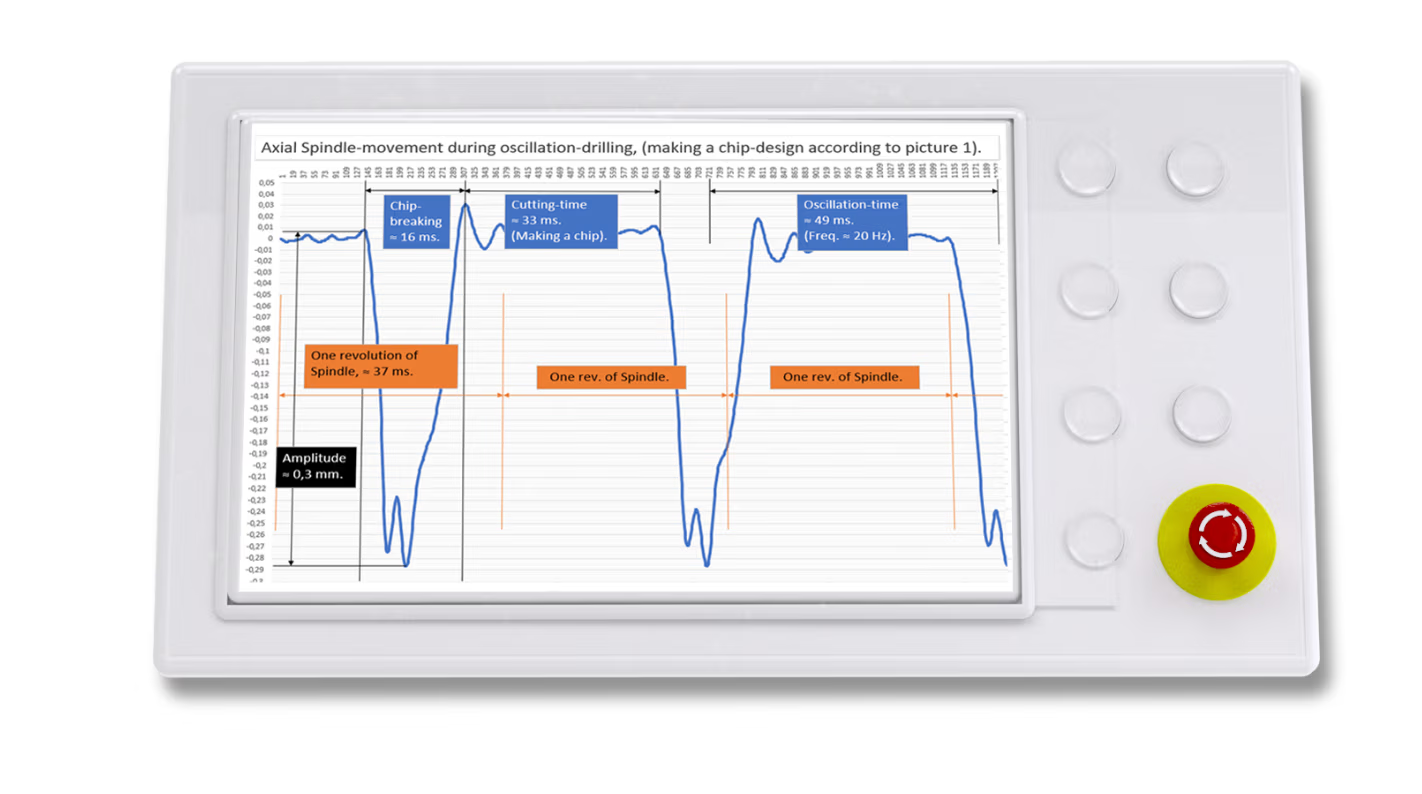

The oscillating movement of Vibicore

The oscillation curve of a typical vibration drill with the Vibicore spindle shows how the vibration movement is superimposed on the feed movement of the drill. This movement pattern can be seen in the illustration above. It differs from previous market approaches and optimises the cutting time through a uniform and controlled chip thickness.

The result: Short chips and outstanding drilling results

The process facilitates dry drilling and enables flawless holes to be produced in a single clamping operation, eliminating the need for reworking or cleaning. This method supports efficient one-way assembly.

Vinnova-funded project: The Vinnova-funded VIBIDRILL project, a collaboration between Cognibotics, VibiCore and RISE, focuses on improving drilling precision and efficiency through advanced technological integration. This initiative utilises VibiCore's vibratory drilling technology operated with SigmaTau's robotic systems. The aim of the project is to increase the effectiveness of robotic vibratory drilling technology to improve hole quality and speed up production processes in large manufacturing environments. The VIBIDRILL project aims to develop and validate this technology to meet industry requirements for precision and efficiency.