This page has been translated automatically.

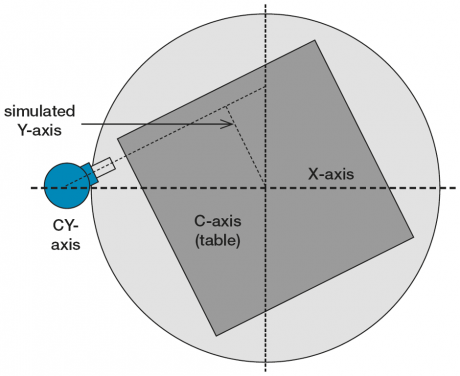

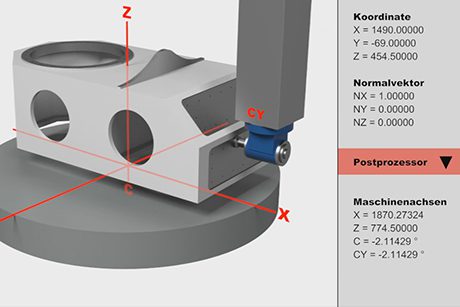

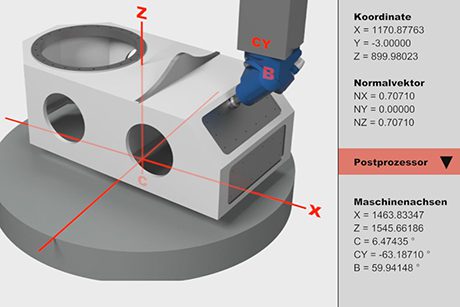

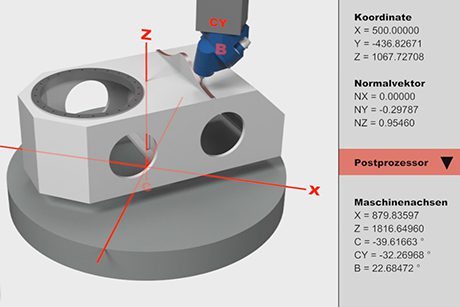

The VTM machine is characterised by another unique technology: Double C-axis interpolation. This technology is used to realise a linear Y-axis through simultaneous interpolation of the rotary table C-axis and the axis-parallel CY-axis in the tool carrier of the RAM unit. This technology offers the following advantages:

- Flexible 5-sided/5-axis simultaneous machining in conjunction with a ELHA HV milling head

- Enormously space-saving, as there is no linear Y-axis

- Highly accurate, thanks to precise SDD table C-axis drive and CY direct drive in RAM

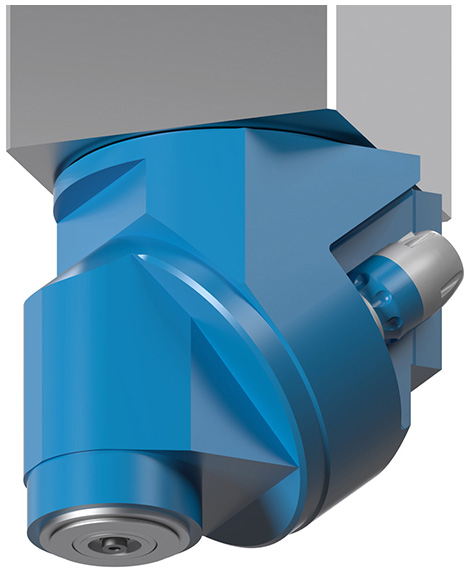

HV swivel milling head

ELHA offers a horizontal-vertical swivel milling head for the VTM series with state-of-the-art drive technology for two ram sizes and different areas of application:

- Ram 500 x 500 mm for light to medium-duty machining

- Ram 600 x 600 mm for heavy-duty machining of preferably cubic workpieces

| Ram | Performance | Speed | Torque |

|---|---|---|---|

| mm | kW (S1) | min-1 | Nm |

| 500 x 500 | 37 | 8.000 | 875 |

| 600 x 600 | 37 | 8.000 | 875 |

| 600 x 600 | 60 | 4.000 | 2.000 |

Application

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policySide machining with horizontal milling head

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policyAngular machining with HV milling head and fixed B-axis

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy5-axis simultaneous machining with HV head and dynamic B-axis