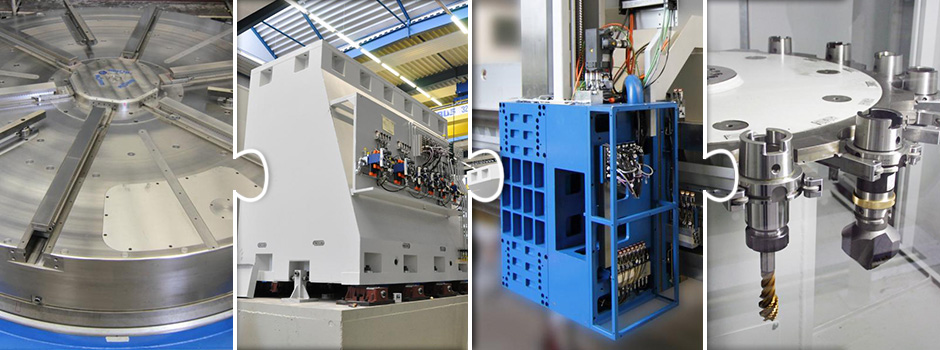

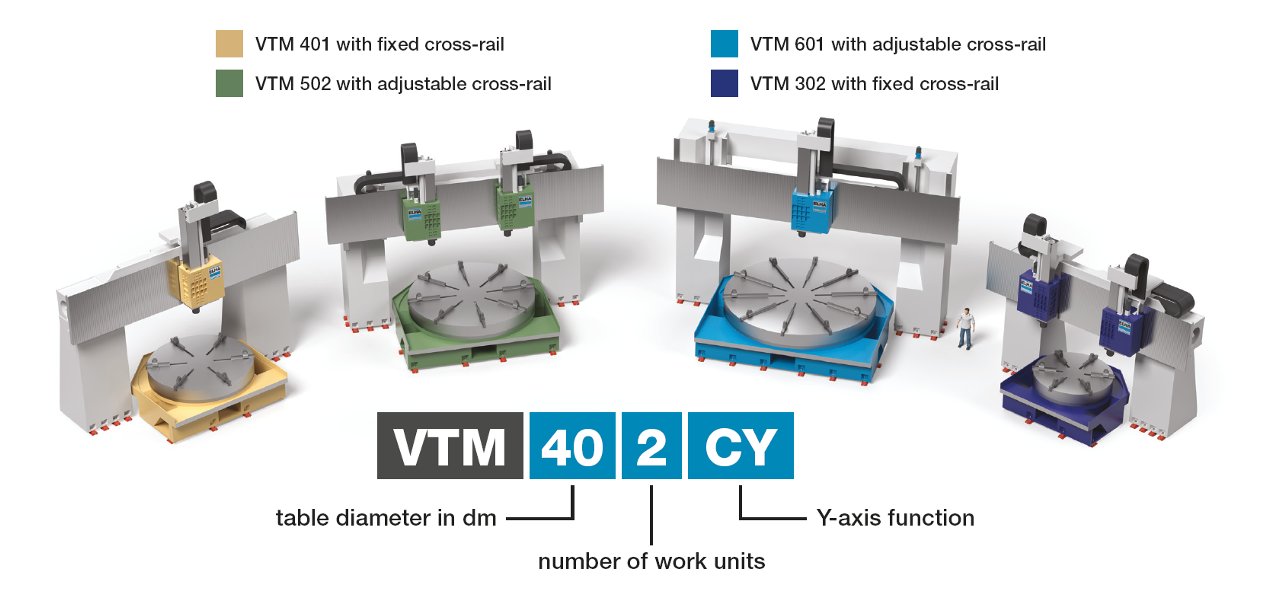

The VTM modular system allows the machines to be configured as multifunctional turning/milling centres for cost-effective complete machining in a table diameter range of 2,500 - 8,000 mm and component heights of up to 5,150 mm. All machines are equipped with two columns and one or two RAM work units. All variants are also optionally available with an adjustable cross beam (W-axis). Further advantages of this concept are the high reliability and availability as well as cost benefits thanks to proven and standardised machine components.

| 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 70 | 80 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| Table diameter | mm | 2.500 | 3.000 | 3.500 | 4.000 | 4.500 | 5.000 | 5.500 | 6.000 | 7.000 | 8.000 |

| Swing diameter | mm | 2.800 | 3.300 | 3.800 | 4.300 | 4.800 | 5.500 | 6.000 | 6.500 | 7.500 | 8.500 |

| Max. workpiece weight | t | 15 | 20 | 30 | 40 | 50 | 60 | 70 | 85 | 110 | 140 |

| Max. turning height | mm | 5000 | |||||||||

| Drive spindle | kW | 37 / 60 / 70 | |||||||||

| RAM cross-section | mm | 360×400 / 500×500 / 600×600 | |||||||||

| Table drive power (S1) | kW | Scalable | |||||||||

| Table torque (S1) | kNm | Scalable | |||||||||

| Max. table speed | min-1 | Scalable | |||||||||

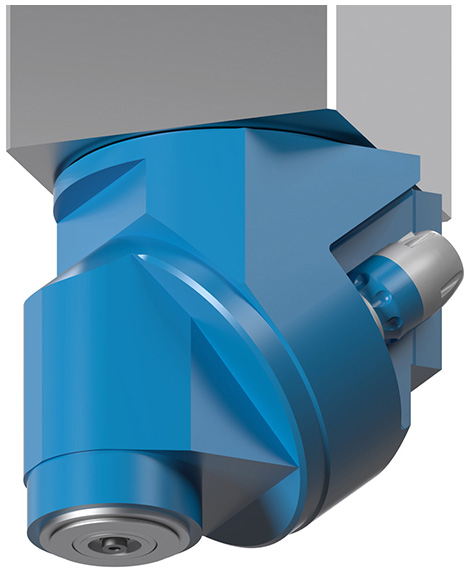

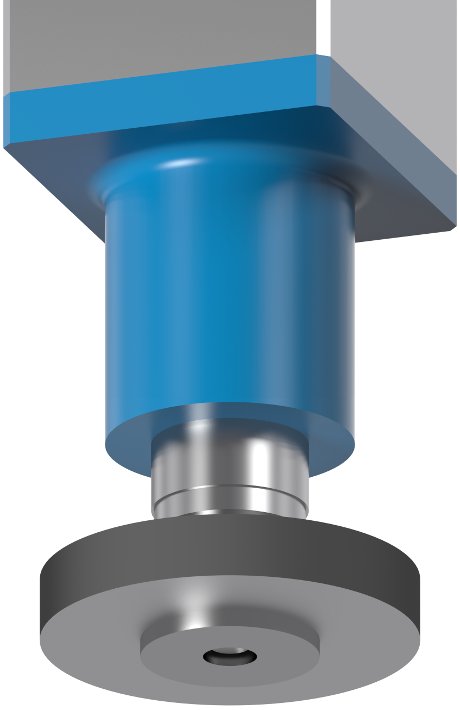

Powerful RAM concept

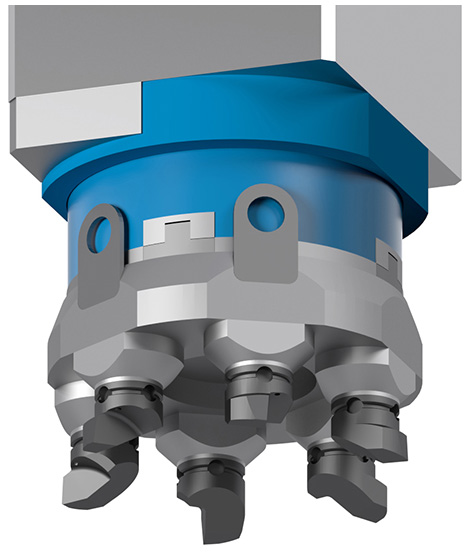

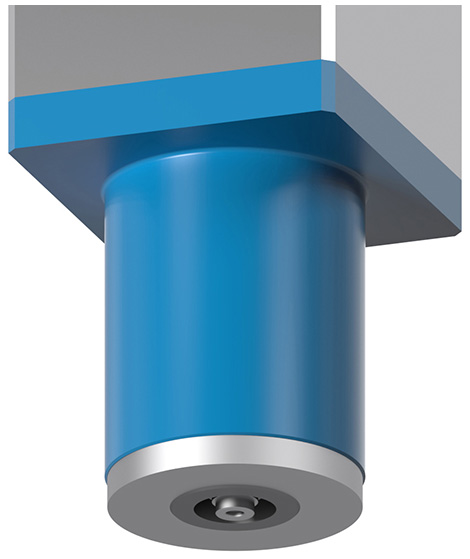

The RAM work units in the VTM series offer a range of innovative technologies for stable and precise high-precision machining as well as extremely flexible options for a wide variety of turning, drilling and milling requirements.

- Wide range of configurations for power, cross-section and joint lengths

- Tool spindle drive with 2-stage gearbox integrated in the RAM

- CFRP drive shaft to protect the drive and ensure high dynamics

- Electrically clamped master-slave rack and pinion drive for maximum dynamics and positioning accuracy in the X-axis for fast drilling and tapping processes

- Sturdy holder with Hirth coupling and power supply for connecting a wide range of attachment units, including self-recognising

| Power / kW (S1) | Ram stroke / mm | |||||||

|---|---|---|---|---|---|---|---|---|

| Ram mm | 37 | 60 | 70 | 1250 | 1600 | 2000 | 2500 | 3000 |

| 360 x 400 | ■ | □ | ■ | □ | □ | |||

| 500 x 500 | ■ | □ | ■ | □ | □ | □ | ||

| 600 x 600 | ■ | □ | □ | ■ | □ | □ | □ | |

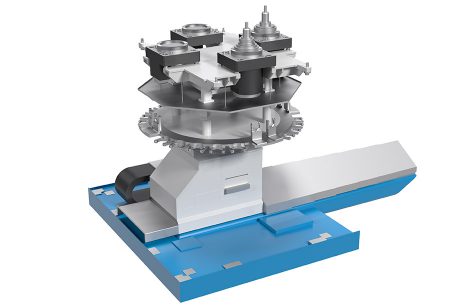

Processes and attachment heads

Tool and attachment head magazines

In addition to standard magazine systems for tools and attachment units, ELHA also offers customised solutions for your production requirements in a wide range of sizes. A wide range of compatible attachment units is also available for a wide variety of applications.