ELHA-MASCHINENBAU is a traditional family business that has been asserting itself for more than 90 years through expertise and comprehensive know-how in machining technology and machine design. ELHA stands for economical solutions in the field of demanding machining tasks. ELHA is constantly evolving to meet new customer requirements.

ELHA in the course of time

1930-1960

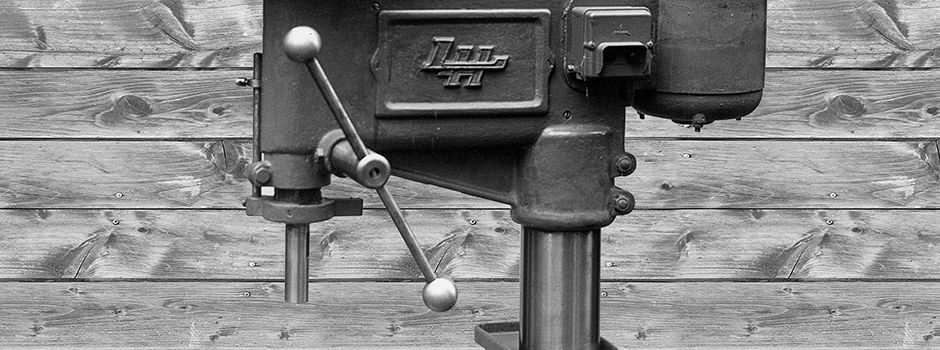

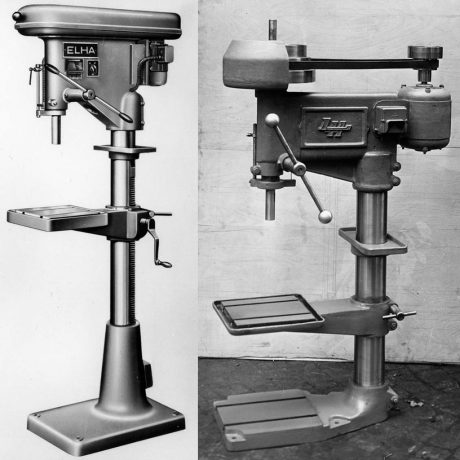

The company ELHA emerges from an electrical trade in 1930. Under the brand name LH, Liemke Hövelhof, machine tools are initially produced for the local wood and metalworking industry.

After the Second World War, the company specialised in drilling machines, which were then marketed under the name ELHA.

1960-1970

The 1960s are characterised by the expansion of the company: the main factory in the centre of Hövelhof is extended by a new administration building and further production halls.

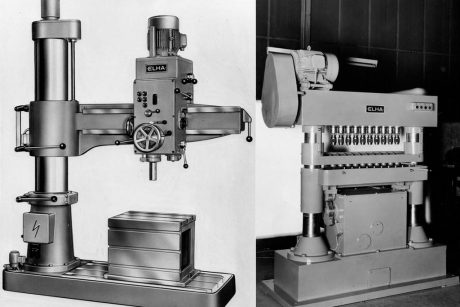

When developing the machines, ELHA focusses on radial drilling machines and launches the first multi-spindle units on the market at an early stage.

1970-1980

The idea of the multi-spindle drilling machine is consistently developed further and the concept is continuously improved through the use of cardan shaft units.

In addition, ELHA expands its product range and successfully builds its first rotary transfer machines.

1980-1990

ELHA continues to expand and the current administration building and a large assembly hall are built.

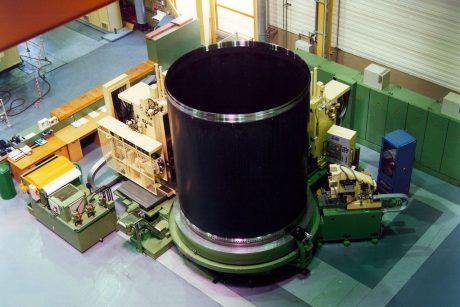

ELHA is thus facing up to new challenges and has been increasingly producing extensive special machines since the 1980s: from transfer lines to special machines that were used, for example, to process the Ariane 5 boosters.

1990-2000

The concept of the FM 3+X production module emerges from intensive co-operation with a customer at the end of the 1990s. This machine is presented to the public for the first time at EMO 1997.

The continuing success of this machine concept confirms the management of ELHA-MASCHINENBAU's decision to build up a new business division for production modules over the past few years.

2000-2010

The 2000s were again characterised by expansion and further development at ELHA.

In 2002, the production modules division is given its own assembly plant on the outskirts of Hövelhof, which is expanded again in 2009 to a total of 4000 m² of office and production space.

The production module series is expanded to include the large FM4+X hd module and the FM3+X hd. The 200th module leaves the factory in 2009.

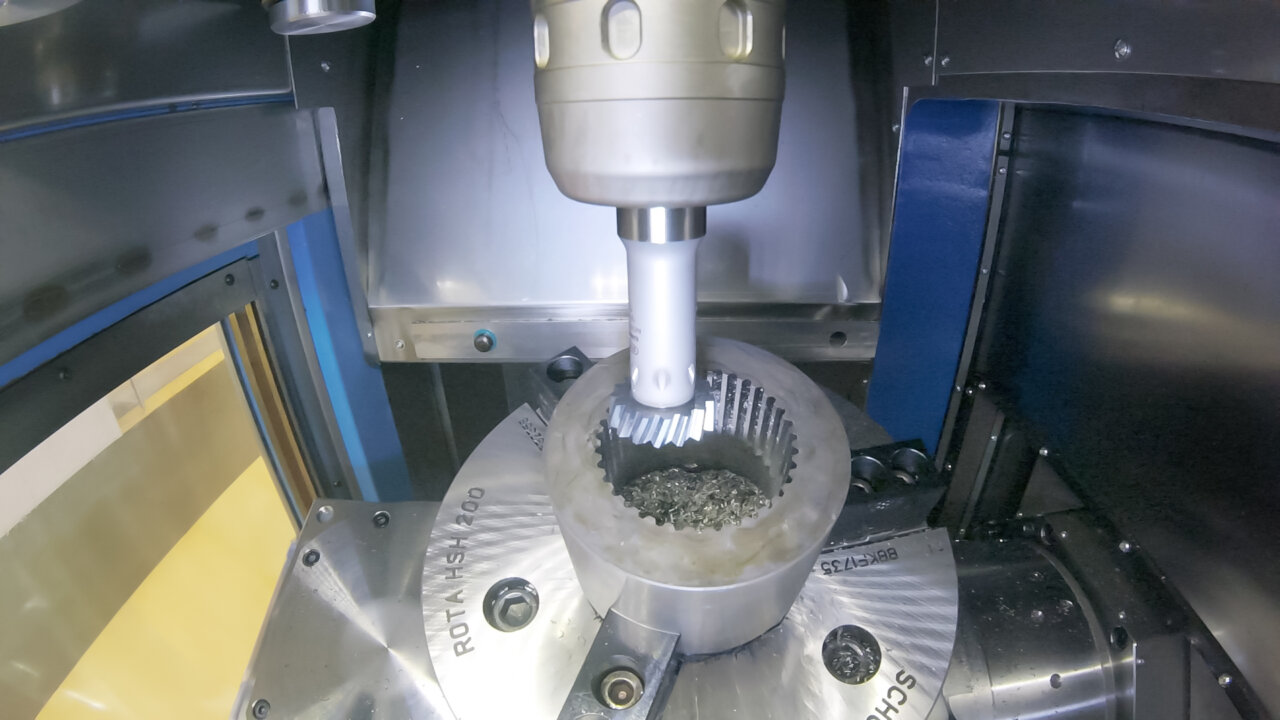

In the XL Manufacturing Systems division, ELHA supplies a large number of special machines and special machining centres to a wide range of industries, with a focus on energy technology and slewing bearings.

2010-2020

The XL Manufacturing Systems division is expanding its product range to include large vertical turning/milling centres (VTM) with a patented ELHA SDD direct table drive based on linear motor technology.

The FM manufacturing modules division launches the FM SMART series. This is based on our FM series and utilises spindle row technology for flexible multi-spindle machining.

Simplification of structures by merging the two divisions XL Manufacturing Systems and Manufacturing Modules in order to respond more efficiently and agilely to customer needs.

Development of iDPS, the system solution from ELHA for greater productivity, efficiency and transparency. The applications can be accessed via end devices in the company network or, with customer approval, worldwide via the ELHA Machine Service Portal. Access from mobile devices is also available as an option.

Significant further development of the spindle row magazine (SRM) for the FM SMART series. Technologically improved rotary table drive Segment Direct Drive (SDD) for the VTx series.

2021

ELHA is changing its sales structure by switching from territorial to project protection. This means that the agencies in Germany can now acquire customers across all territories.

New VTG machine series: these are large vertical turning and grinding machines. These are used for finishing large-format workpieces by means of grinding, turning and drilling.

Under the label "Retrofit by ELHA", we have many years of experience in the field of machine conversions, modernisations and general overhauls. We utilise this expertise not only for the reconditioning of our own production systems, but also for systems from all well-known manufacturers.

2022

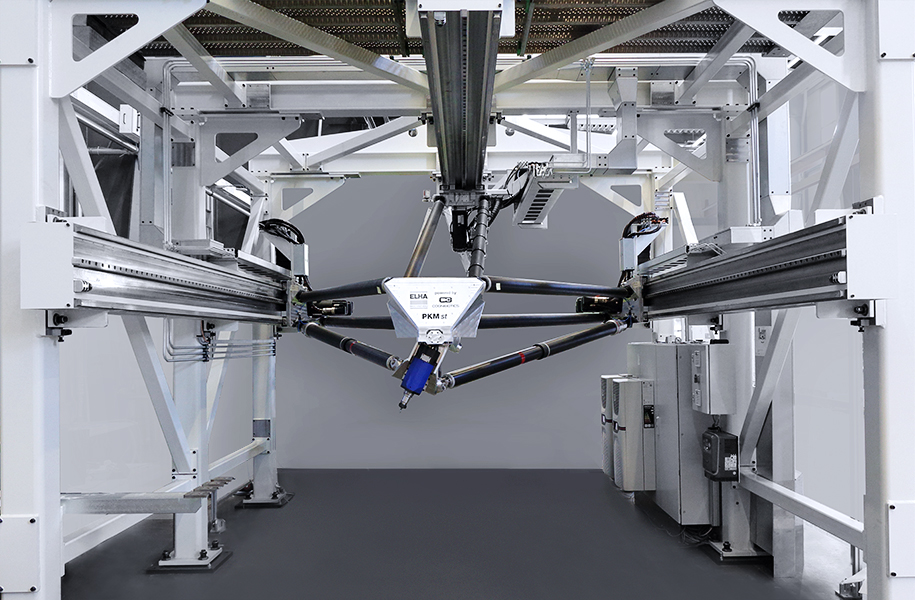

The parallel kinematics module (PKM) was developed together with our partner Cognibotics. The PKM is a modular machine with an innovative structure that offers high dynamics and path speed with repeatable positioning. It combines the advantages of machine tools and flexible robot processing, enables precise processing of large components and acts as a technological bridge in production.