Consistent automation and short changeover times enable competitive production even in high-wage countries. With this in mind, ELHA FM machines have been developed for use in partially or fully automated stand-alone or interlinked lines and can therefore be efficiently integrated into corresponding production environments.

Systematics

The 2-axis robot loads the workpiece pallets directly into the work area. The workpieces are then picked up by the clamping device using the pick-up method. This process enables flexibility in the alignment of the pallet accumulation conveyor. A standard 5-axis robot with different gripper variations offers the greatest possible flexibility in automation. The robot is positioned in front of the work area and loads the workpieces directly into the clamping device. In addition, secondary operations such as deburring or labelling can be carried out during machining. A linear shuttle is a technically simple solution for providing the workpieces in the work area. This means that the workpieces can be transported with just one mechanical axis from a pallet accumulation conveyor or after manual loading.

One module with many possibilities

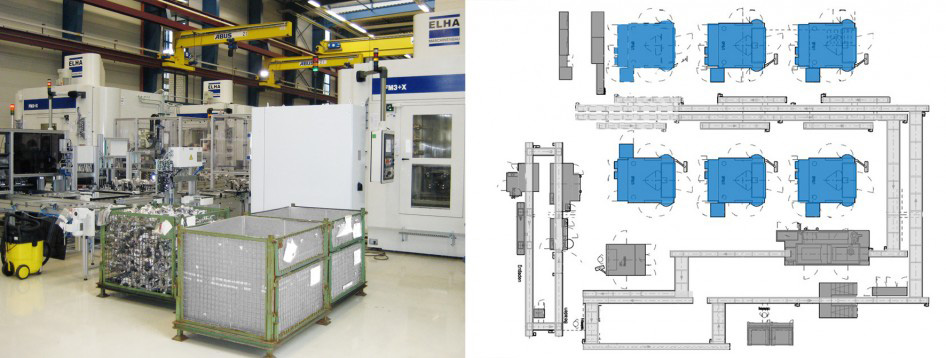

Automated complete solutions perform many different operations and often replace a series of standard machines. The complete systems consist of several interlinked machines or system components. Specialised CNC machines are integrated as well as external units, e.g. for broaching, hardening, assembly and hard machining. Peripheral tasks such as handling, deburring, cleaning and washing are also carried out.

More system examples

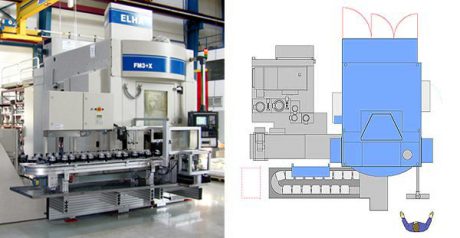

FM 3+X as a single module

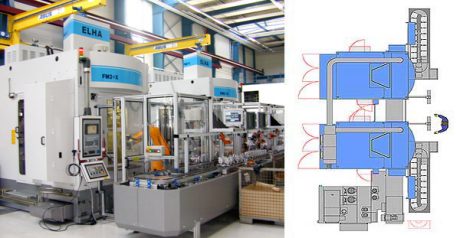

FM 3+X as double module

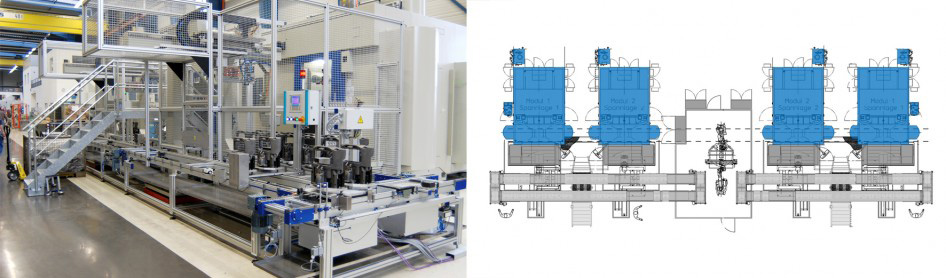

FM 4+X in pairs as a double module

FM 3+X with total interlinking