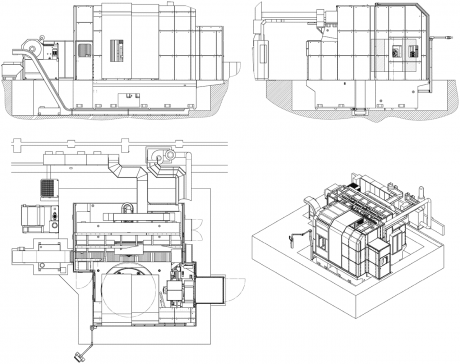

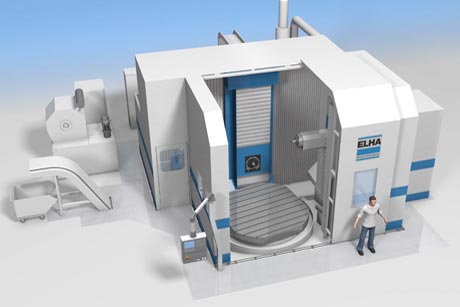

This machine was primarily designed for multi-spindle, horizontal drilling and milling of heavy rollers. In order to be able to machine other workpieces as well, the first unit was designed as a dynamic box-in-box unit. The box-in-box unit is characterised by the increased X-travel and a more powerful work spindle.

The three-part machine frame of the box-in-box unit and the two-part machine base are made of vibration-damping composite material. The 2,500 mm CNC rotary table was designed for particularly heavy workpieces weighing up to 45 tonnes. The rotary table can be used to position any angle with an accuracy of ±3 arc seconds.

The use of manually adjustable, automatically interchangeable twin-spindle drilling heads in both units can significantly reduce the machining time. Two automatic tool magazines can also hold additional drilling and milling tools.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy| Technical data | ||

|---|---|---|

| Travel distance | X1 / X2 axis | 2,500 / 200 mm |

| Y1 / Y2 axis | 1,800 mm | |

| Z1 / Z2 axis | 1,000 mm | |

| Feed rates | Max. maximum speed | 30 m/min |

| Main drive unit 1 | Max. power S1 / S6 | 28 / 42 kW |

| Max. torque | 534 / 2,136 Nm | |

| Max. speed | 3,000 rpm | |

| Main drive unit 2 | Max. power S1 / S6 | 33 / 45 kW |

| Max. torque S1 / S6 | 157 / 215 Nm | |

| Max. speed | 10,000 rpm | |

| Rotary table | Diameter | 2,500 mm |

| Max. speed | 6 rpm | |

| Tool magazine | Tool places | 3 +MSK |

| Tool holder | HSK-A 100 | |

| Dimensions | Space requirements | 11.7 x 9.3 x 6.0 m |

| Total weight | 166,000 kg | |