ELHA at the EMO 2025 in Hanover

22-26 September 2025 / Production that adapts, not the other way round.

At EMO 2025, you can experience how ELHA-Maschinenbau creates machine concepts: not from the standard modular system, but from specific component requirements. Whether series production in the automotive sector, large parts in the energy industry or customised solutions in classic mechanical engineering, we develop technologies that integrate seamlessly into your existing production processes, not the other way round.

The focus is on components and applications from the fields of infrastructure, aviation, defence and more. Using selected exhibits, we show how we combine precision, process reliability and cost-effectiveness with sophisticated technology, many years of industry experience and a clear focus on customer benefits.

Visit us at EMO 2025 in Hanover and talk to our experts about your production.

We look forward to meeting you in person at our booth C49 in hall 12.

You were there? Then take a look at our Trade fair review to.

Infrastructure

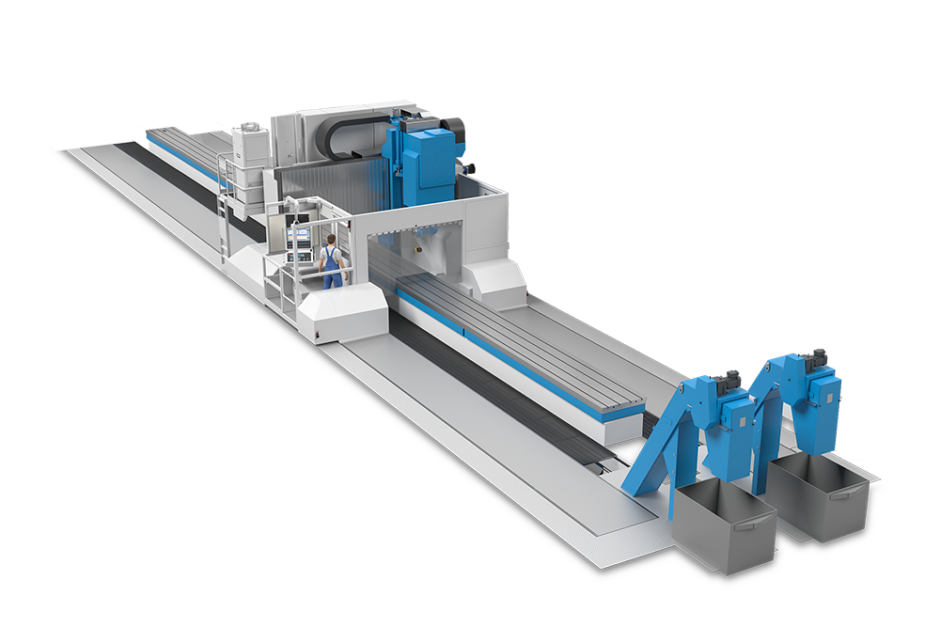

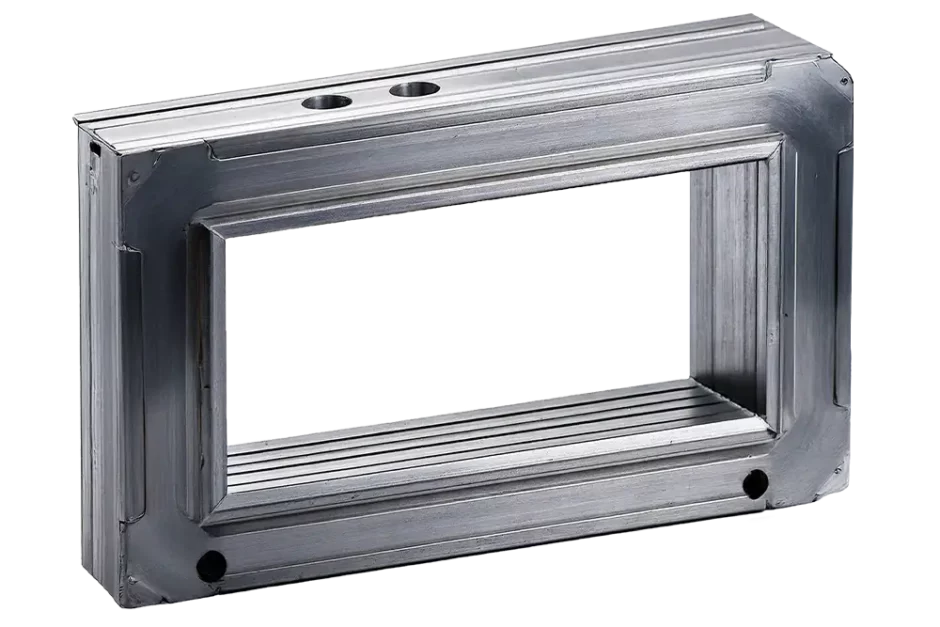

SPX - special machine for the highest demands in track construction.

Powerful milling spindles, long travel distances and robust design for long-lasting precision. Typical applications: Drilling, tapping and milling of large components.

Efficient machining thanks to robust customised solutions from ELHA. Typical workpieces in use: tongue support, rail, centrepieces

Automotive

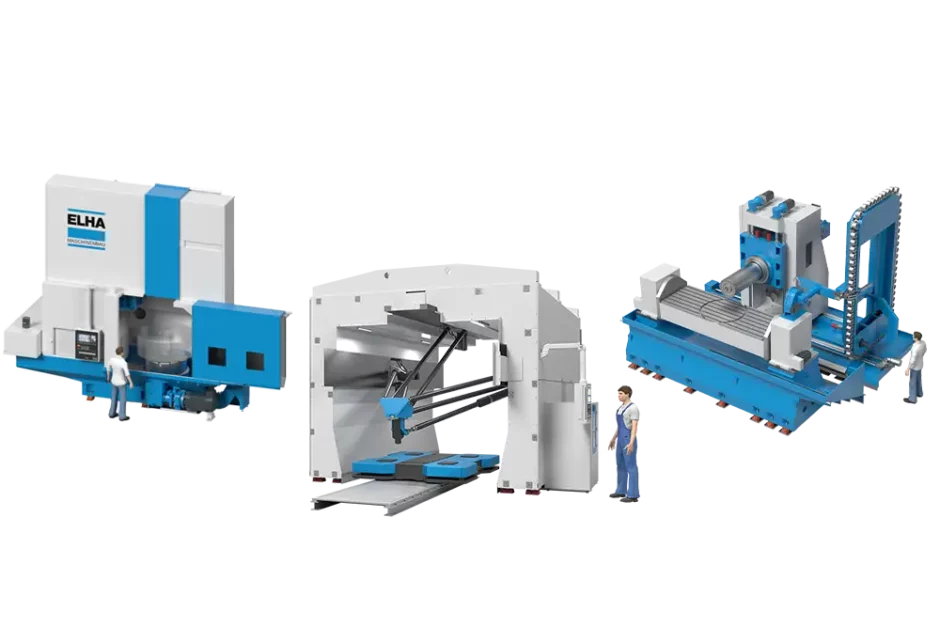

Maximum productivity for series production.

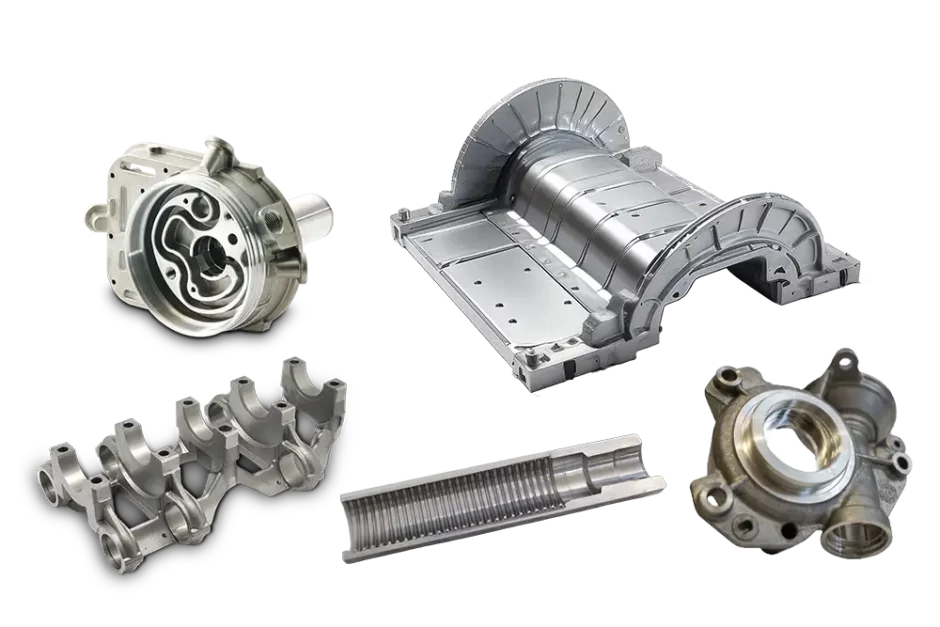

Our production modules and the parallel kinematics module (PKM) deliver top performance for OEMs and suppliers - tool change-free, precise and efficient. Ideal for complex components and high quantities.

Typical workpieces from series production:

Rotor shaft, steering tube, worm housing, gigapress part. Perfect solutions for the dynamic automotive industry.

Energy

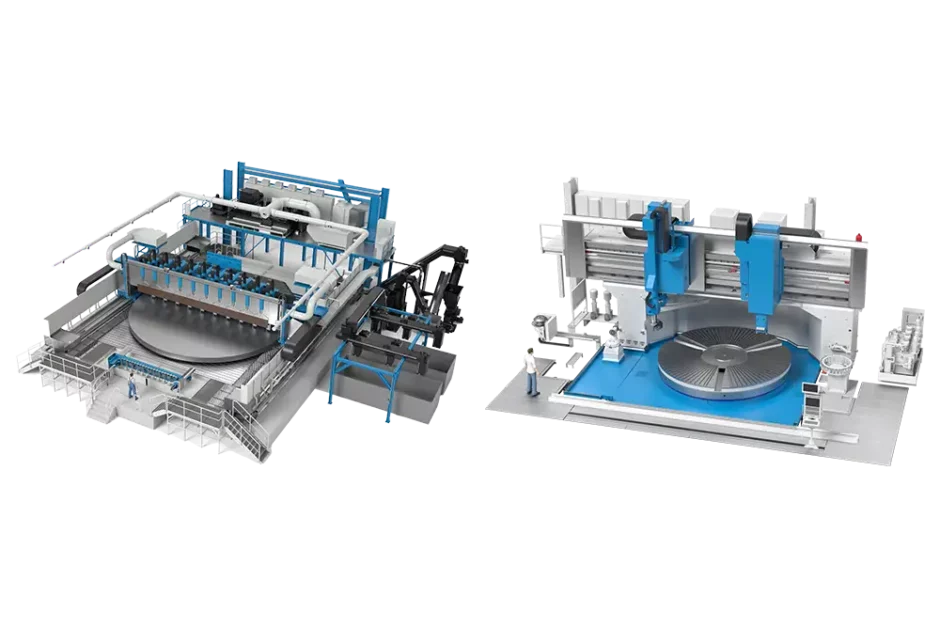

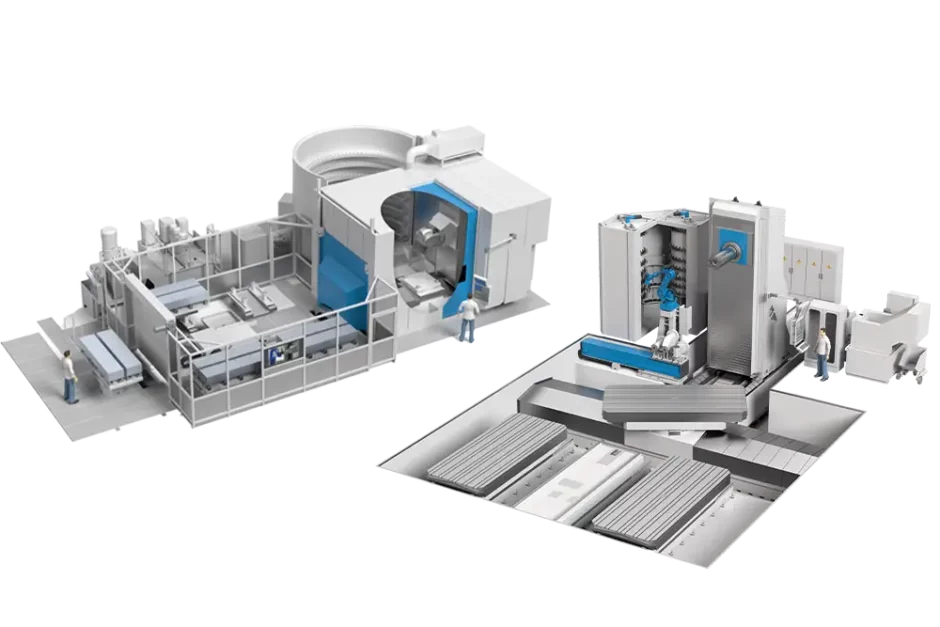

Vertical turn-mill centres for large workpieces.

Our VTM and VTG machines fulfil the highest requirements in energy technology: with precision, efficiency and flexibility in the machining of solid components.

Application examples from energy technology:

Rolling bearings, slewing bearings. For stable processes and durable components.

Aerospace

Maximum precision for the aerospace industry.

Our VTM centres and the PKM module are made for difficult-to-machine materials such as titanium, with powerful spindles and extremely stable mechanics.

Typical applications in the aerospace industry:

Aircraft leg and turbine parts. For reliable performance with maximum precision.

General machining

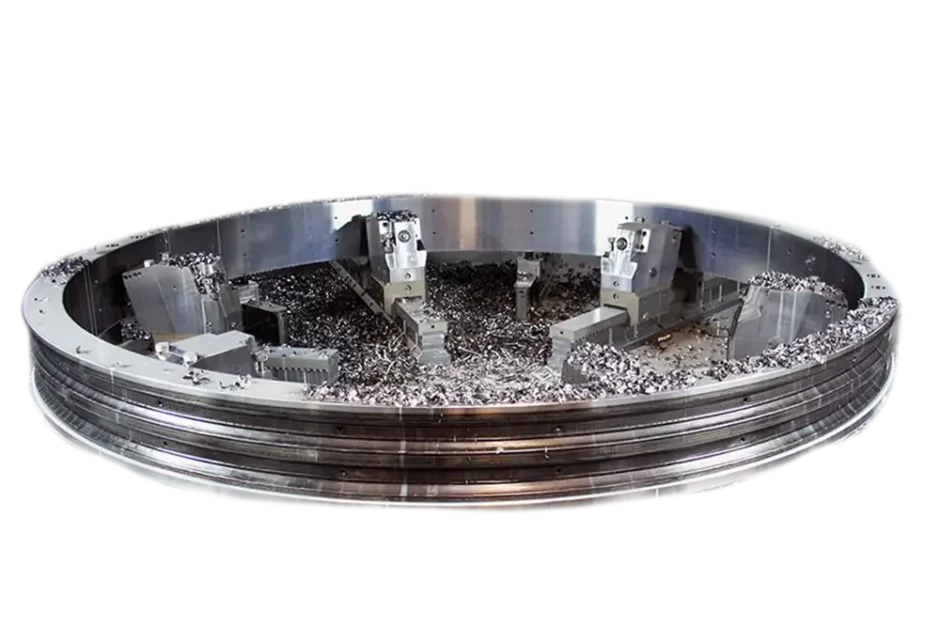

Innovative customised solutions for complex requirements.

From vertical turn-mill centres to rotary table or special machining centres: ELHA is your partner for individual solutions in mechanical engineering.

Workpieces in a wide range of dimensions and requirements: Production parts for assemblies, flanges, slewing rings. For precision and flexibility in individual and series production.

Trade fair information

Date: 22-26 September 2025

Location: Hanover

Stand: Hall 12, Booth C49

https://emo-hannover.de/