Agree to data transfer to YouTube and play video - Privacy policy

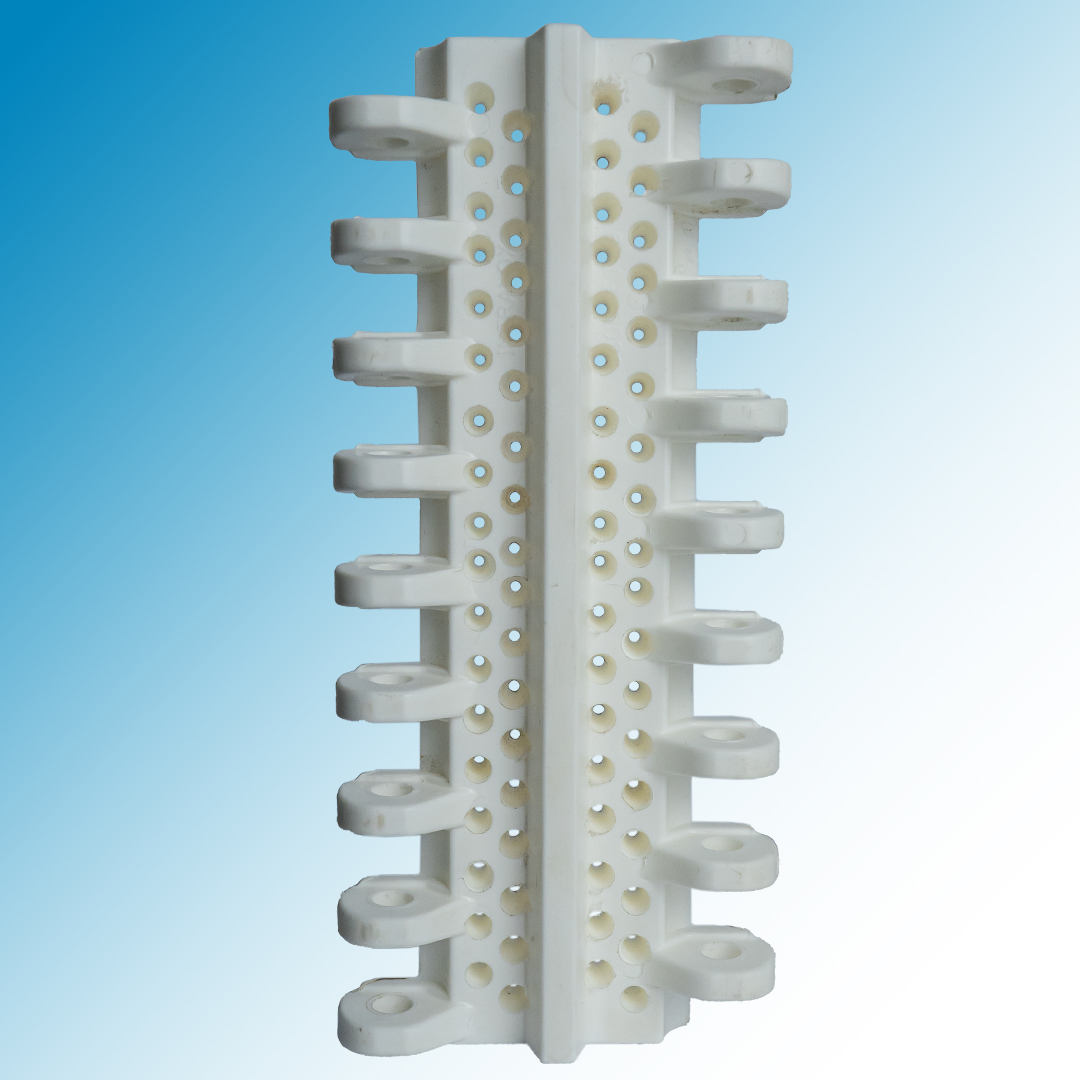

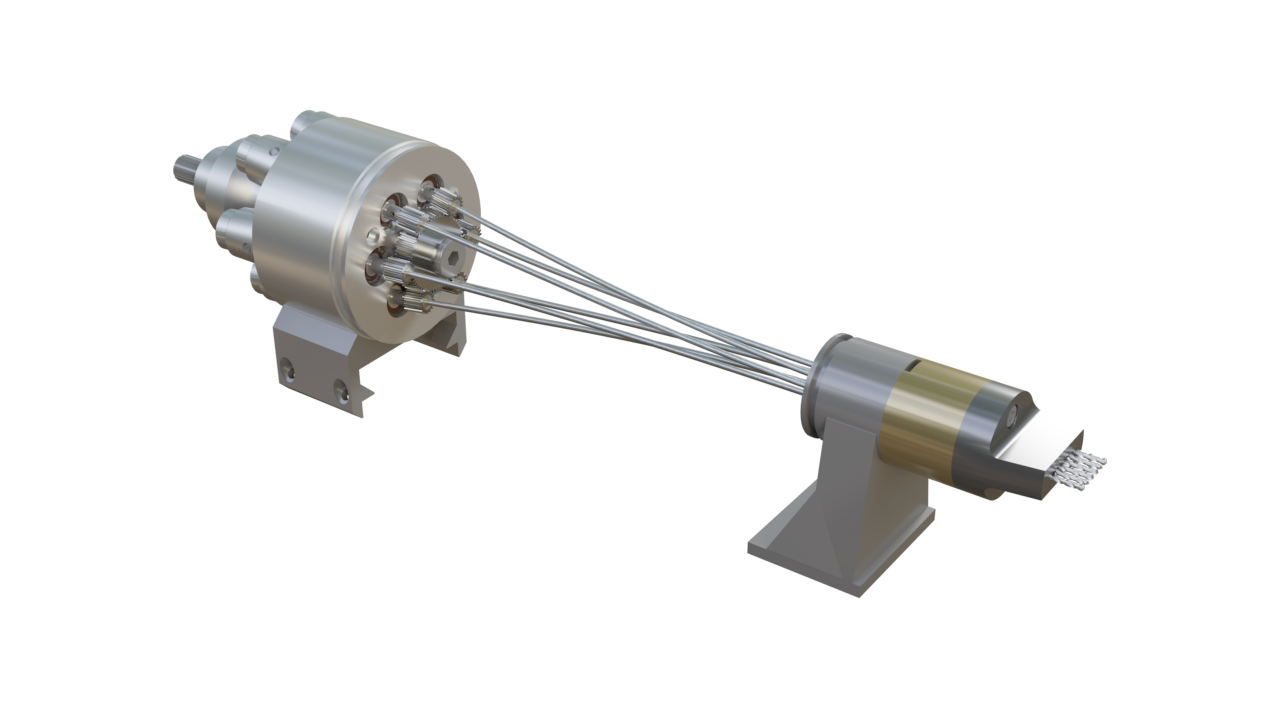

Agree to data transfer to YouTube and play video - Privacy policyContrary to all tendencies of social distancing rules, we are moving closer together. However, not in the interpersonal area - where distance is currently necessary and sensible - but we are bringing tools closer together than is usual in mechanical engineering. This means productivity in the tightest of spaces, even with small components. This is made possible by the use of micro multi-spindle technology. Spindle and tool spacing of approx. 0.2 mm can be achieved. More productivity in the smallest of spaces is hardly possible, is it? Machining components with intricate dimensions requires maximum precision and often takes a comparatively long time. With our multi-spindle machines, drilling, tapping or screwing is not only extremely precise, but also extremely fast. Several drills are driven simultaneously with just one drive, enabling hole patterns with unimaginably small distances.

This is the optimum solution for multiple drill holes with extremely small distances.

Meinolf Wolke

Your benefits

- Multi-spindle machines with extremely close centre distances

- Various bores with different speeds in a single operation

- Optimum solution for multiple drilling, tapping and screw connections in large-scale production

- Can be used in CNC and cutting applications

- Customisable hole pattern

- Integration into fully automated production processes and Industry 4.0 applications