Review of a successful trade fair

Five intensive days at the trade fair are behind us. From 22 to 26 September, we from ELHA-MASCHINENBAU were represented at EMO Hannover 2025. This trade fair is always an excellent opportunity for us to present our technologies to an international audience and to gain valuable impetus from the industry through direct dialogue.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy

Focus on technologies at the EMO in Hanover

This year, our trade fair presence centred on machine concepts that do not come from a standard modular system, but are developed specifically from the requirements of individual components. Our systems fit seamlessly into existing processes, whether series production or customised solutions. This is precisely what makes the difference and was one of the key points of discussion at EMO Hannover 2025.

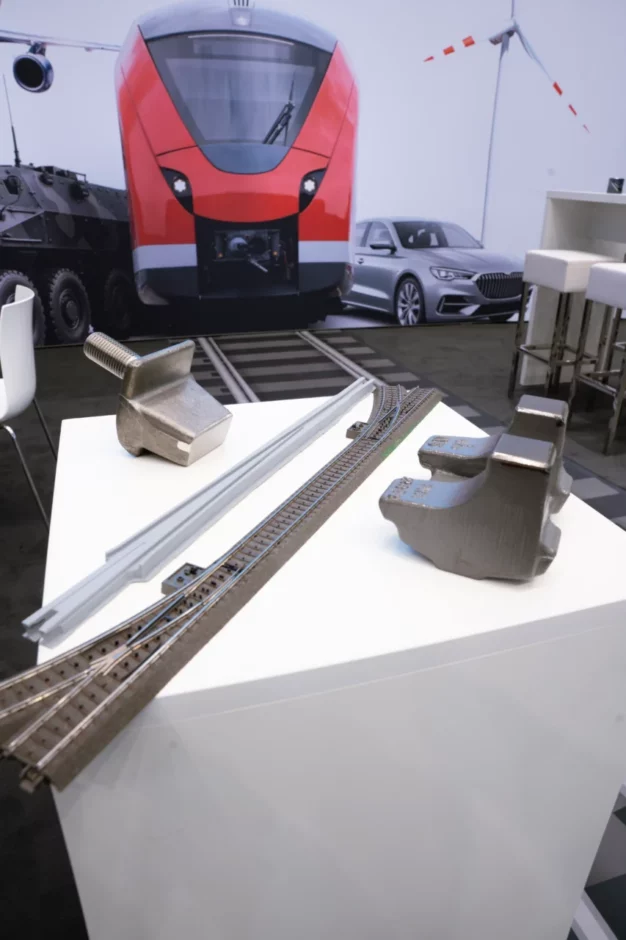

We presented selected exhibits at various stations: the production module, our vertical turning/milling centres (VTM & VTG), the parallel kinematics module (PKM) and workpieces that we have already machined on our ELHA machines in the past.

Another highlight was the look at the sectors in which our technologies are already being used today, from energy, infrastructure, automotive and defence to aerospace.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy

Parallel kinematics module (PKM)

Technology carrier with versatile applications

One of the highlights of our trade fair appearance at EMO Hannover 2025 was the parallel kinematics module. Our colleague Sven presented it in a video, live from the trade fair stand. In miniature format, it demonstrated how the gap between serial robotics and conventional machining centres can be closed.

The PKM serves as a technology carrier to which various systems can be connected. Examples are 3D laser cladding for large structures, the highly dynamic processing of composite materials with Vibration Drilling or the flexible drilling and milling of structural components such as Giga Press parts.

These examples show just some of the possibilities that can be realised with the PKM. You can find further processes and applications here.

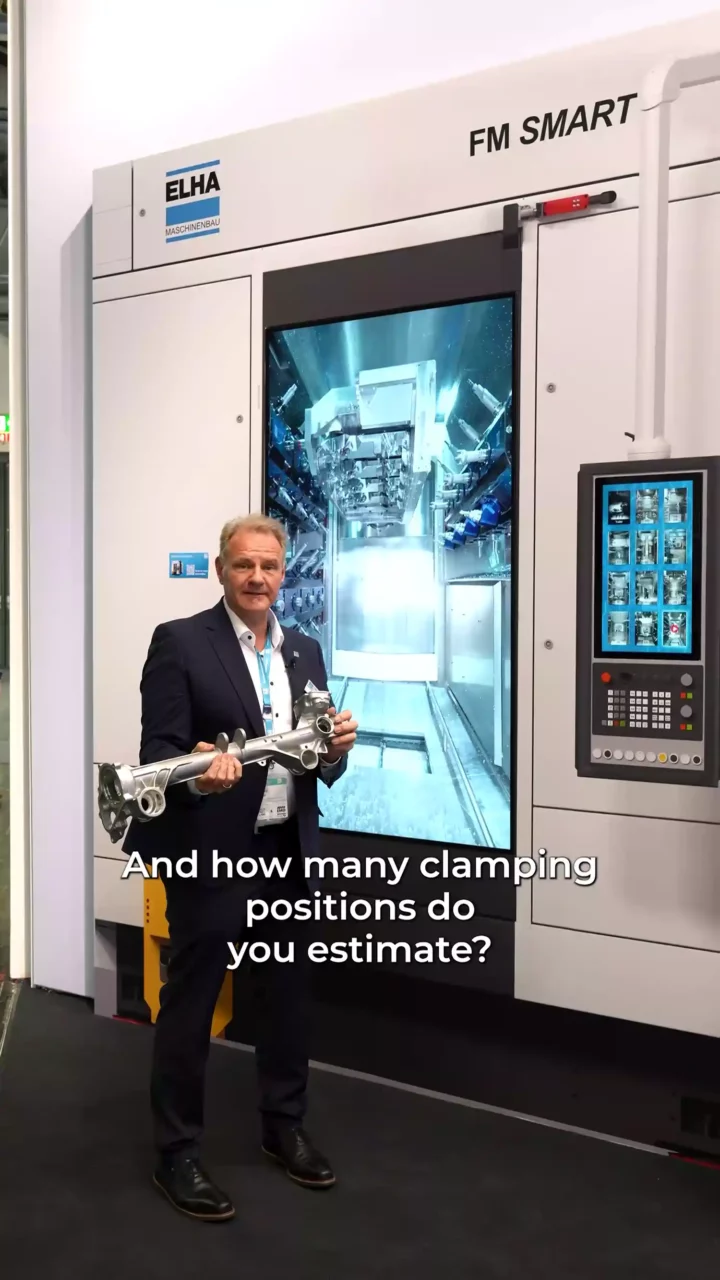

Production module

Advantages for a wide range of industries

Our production module can be used in many industries and impresses with its modular design. In this video, our colleague Meinolf shows what this looks like in practice using a real workpiece: a 600 mm steering housing. This shows what EMO Hannover 2025 visitors particularly appreciate: practical solutions with clear advantages.

The modular design enables complete machining in just one clamping position. The workpiece can be machined from up to six sides, realised by the combination of fifth axis and clamping device. The next tool is already in position while one part is being machined. This ensures maximum efficiency, high precision and short throughput times.

Do you need more information about our production module? Here for more information.

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy

Agree to data transfer to YouTube and play video - Privacy policy

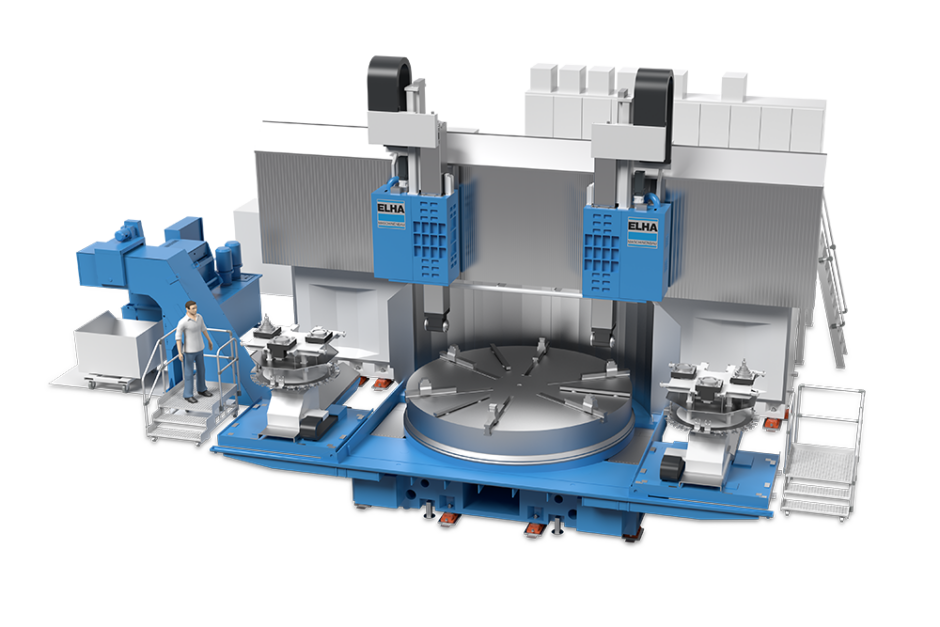

Vertical turn-mill centres (VTM & VTG)

Efficient machining for large, complex components

Another focus of our presence at EMO Hannover 2025 was the Vertical Turn-Mill Centres (VTM & VTG). This concept was specially developed for industries such as renewable energies or aerospace, where large and complex components need to be machined with the highest precision. Carina presents this in the following video.

Turning, milling, drilling and even grinding - the VTM/VTG combines several manufacturing processes in one machine and therefore offers maximum flexibility. This approach leads to significant productivity gains, especially for large and complex components.

The concept has a modular design and is suitable for a wide range of applications. In addition to slewing rings, engine components and cubic parts can also be machined efficiently. Thanks to our in-house developed, dynamic and high-precision rotary table drive (ELHA SDD) in combination with a 2-axis milling head, even 5-axis machining is possible without integrating an additional linear movement of the rotary table. This principle is known as the double transmit function.

Thanks to complete machining in just one clamping operation, VTM technology reduces set-up times, improves dimensional accuracy and increases process reliability.

Does that sound interesting? Here for further information.

Encounters at the trade fair

In addition to our exhibits, it was above all the personal dialogue that made EMO 2025 so valuable for us. We had many interesting discussions, made new contacts and deepened existing partnerships. This dialogue in particular is crucial for us to continuously develop our technologies.

Do you have any questions about our products? Then please feel free to contact us:

Conclusion and outlook

EMO 2025 in Hanover was a complete success for ELHA-MASCHINENBAU. We would like to thank all visitors who took the time to visit us at our stand in Hall 12, C49.

After the trade fair is before the trade fair: We will continue to work on developing machine concepts that are precisely tailored to our customers' requirements, from infrastructure and aerospace to customised special solutions.

Don't want to miss anything? Then follow us on LinkedIn!