How gigacasting is revolutionising the automotive industry

Gigacasting, or megacasting, has been an extremely popular technology in the automotive industry for some time now. With gigacasting, large, structural vehicle components are manufactured in one piece using aluminium die casting. This technology drastically reduces the number of individual parts, which lowers production costs and simplifies assembly processes. But how can these components be processed precisely? This is where the combination of gigacasting and parallel kinematics comes into play - for efficient and high-precision post-processing of large aluminium components.

Tesla is the pioneer of this production technology, but companies such as Toyota, Hyundai and Volvo are also increasingly relying on gigacasting to realise lighter vehicle structures. This advantage plays an important role in electromobility in particular, as it reduces the vehicle weight and thus increases the range.

The challenge: Precise post-processing of gigacasting components

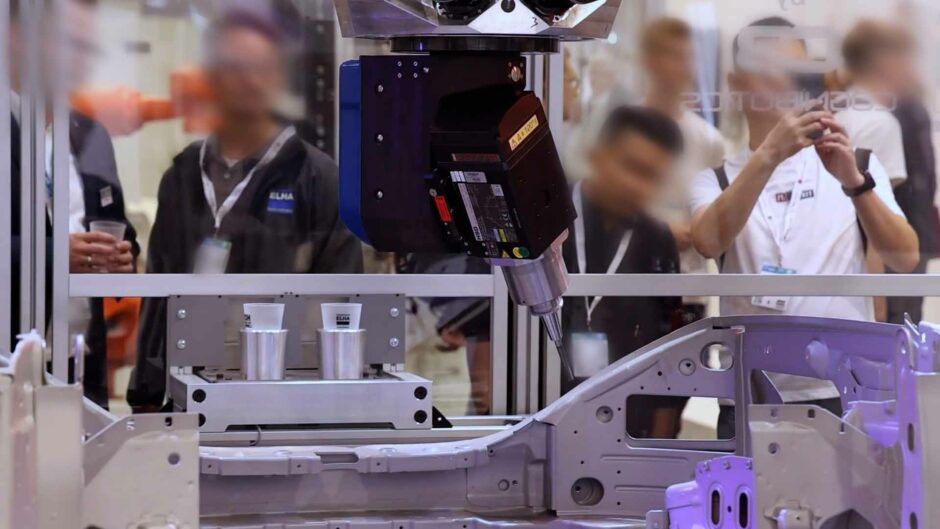

While gigacasting has a number of advantages, the post-processing of these large-format aluminium parts presents a challenge. Components such as the underbody or front and rear frames of a car must be machined with the utmost precision and efficiency to ensure a perfect fit and functionality.

Our PKM, the perfect solution for gigacasting parts

- Flexibility:

- Adaptation to different component sizes and shapes without time-consuming changeover times

- Perfect for various gigacasting components (from structural components to bodywork elements) - Inline production:

- Can be perfectly integrated into existing production lines for maximum efficiency

- Continuous processing without additional transport routes and changeover times - Speed and precision:

- Feed speed up to 50m/min

- Highest contour accuracy for a precise fit - Optimum size for large components:

- Developed for processing large-area structures

- Ideal for gigacasting components

- High dynamics made possible by strong jerk and parallel kinematics

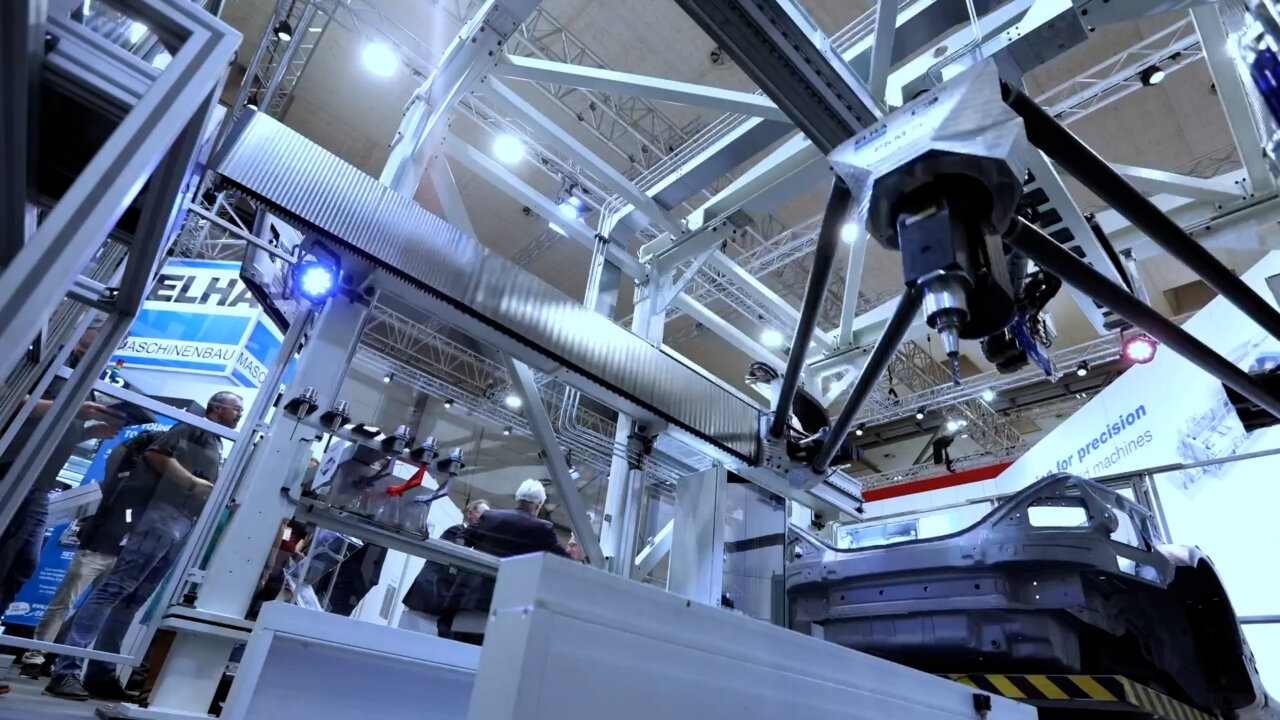

Gigacasting & parallel kinematics: Efficient gigacasting machining with our PKM

With our PKM, we offer a high-performance solution for the precise and fast post-processing of gigacasting parts. Gigacasting is the future of the automotive industry and is here to stay. Companies need to rethink, as the large presses for gigacasting parts take up an enormous amount of space in production. Our PKM can be used flexibly, can be easily integrated into existing processes and impresses with its precise machining.

Would you like to find out more? Contact us and we will help you find the optimum manufacturing solution for your gigacasting components.

Get non-binding advice now: Contact form

Find out more here:

PKM can be used in various areas

Our parallel kinematics module is a modular machine that can be equipped with a wide range of end effectors. Compared to serial robots, it offers an increase of 10 to 15 times higher stiffness and accuracy at the end effector. The innovative mechanical structure allows geometric variations of the base frame and therefore customisation of the working space. The PKM distributes loads to the building foundation and offers maximum flexibility during installation, as no additional foundations are required. In addition, our PKM can be used in hybrid production in various processes.