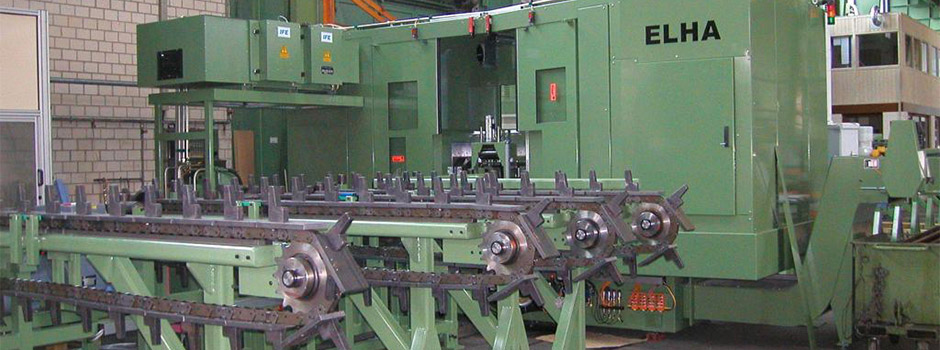

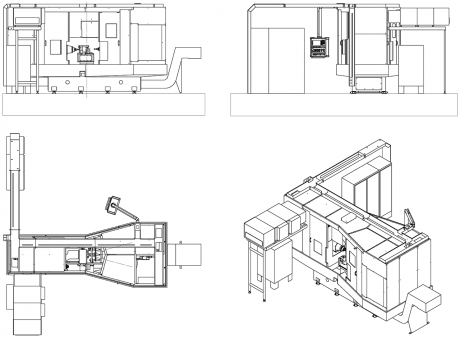

This machine is suitable for drilling and both-sided chamfering of rail profiles in various shapes and dimensions. The drill-machining is carried out with a ± 15° pivoting 2-axis-unit. This unit is equipped with an additional 6-ply tool changer. The rear-side chamfering of the bore holes is carried out with a non-pivoting 2-axis unit on the opposite side.

To achieve a constant both-sided chamfering despite large tolerances at the work piece, the machine was equipped with patented software. This program enables chamfering with a tolerance of ± 0,3 mm.

The feeder-magazine next to the machine holds up to 10 rails. The belt conveyor transports raw-part rails up to a length of 15 m into the machine. To be able to position the rail exactly the machine is equipped with a CNC-controlled rail positioning device. After processing the finished rails are picked-up by a feeder-magazine.

| Technical Details | ||

|---|---|---|

| Traverse path | Y-axes | 100 mm |

| Z-axes | 320 mm | |

| rail transport | 18000 mm | |

| tool magazine | 450 mm | |

| pivoting range | ±15° | |

| Feed rates | max. speed | 30 m/min |

| rail transport | 10 m/min | |

| Main drive | max. capacity S1 / S6 | 20 / 25 kW |

| max. speed | 4000 rpm | |

| tool holder | SK 50 | |

| Tool magazine | tool slots | 6 |

| max. tool length | 230 mm | |

| max. tool diameter | 60 mm | |

| Parts magazine | rail length | 1000-15000 mm |

| contact face length | 2500 mm | |

| conveying velocity | 6 m/min | |

| Dimensions | space assignment | 37.2 x 6.7 x 3.0 m |

| total weight | 37500 kg | |