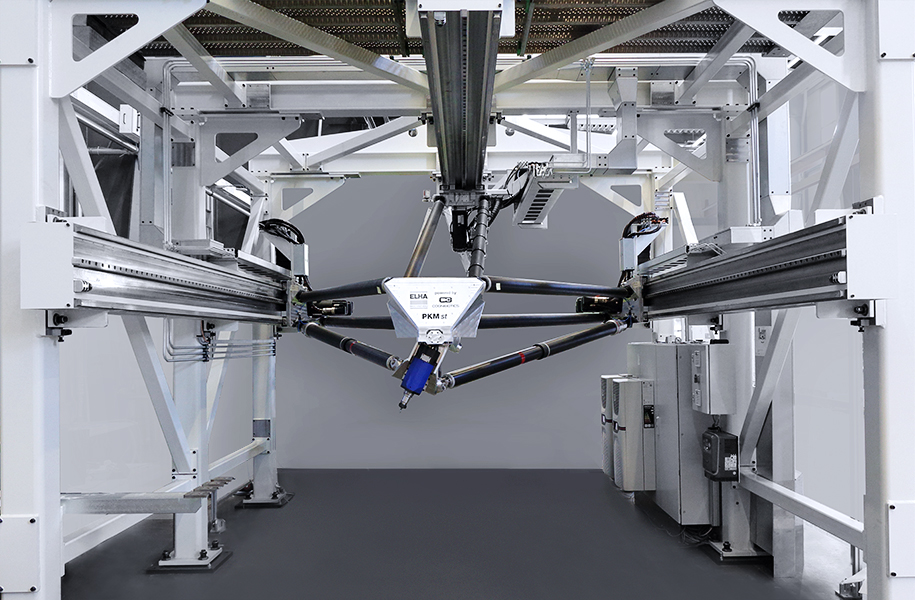

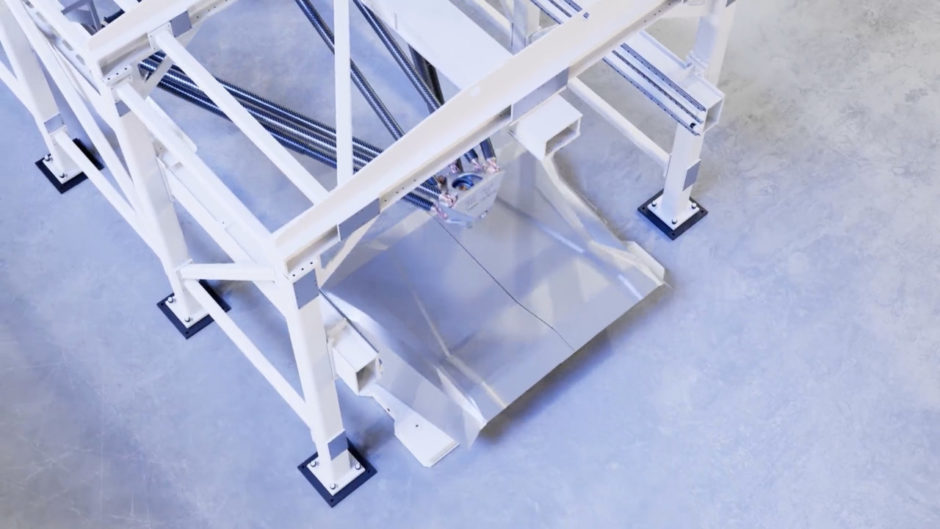

The ELHA Parallel Kinematics Module (PKM) can be equipped with almost any end effector for a wide range of manufacturing processes. Compared to a serial robot, stiffness and accuracy at the end effector can be increased by a factor of 10 – 15. The mechanical structure of the ELHA PKM allows geometric variations of the base frame and thus the size of the workspace. Compared to a large-sized arm robot, the loads on the building foundation are distributed over the frame and transferred to a larger floor area. This results in maximum flexibility for the installation site as no foundations are necessary.

Inline machining modules from ELHA, built according to the PKM concept, combine the advantages of classic machine tools and flexible robot machining. A wide variety of components, including large castings, can be machined directly “inline” with unprecedented precision and flexibility. By using several modules, different machining operations such as laser cutting, milling and friction stir welding can be realised directly in one line. The modules can be mounted in any orientation of the working plane and adapted to the respective working area. The parallel kinematic concept achieves higher accuracy and rigidity compared to a conventional robot arm manipulator, while retaining many aspects of flexibility.

Modules based on parallel kinematics close the gap between classic machine tools and conventional arm robots. The solution offers a high degree of flexibility and can be integrated into existing or new production lines. A large working range and extreme speed are the main features of the PKM. This was developed in cooperation with our partner Cognibotics.

The PKM is a lightweight, the arm system has a low weight, thus highest accelerations are possible. Weight-optimised structures with carbon rods ensure up to 20 times less moving mass. A special feature is that the moving mass does not change when the working range is increased. At the same time, the PKM is easy to assemble and disassemble. The application carrier is connected to the three guide beams via cardan joints and carbon rods. For full 5-axis capability, two telescopic rods are added. As an alternative to the telescopic rods, a 2-axis hv head can also be used.

Due to the superior rigidity, ten to twenty times higher accuracy is achieved compared to serial robots, making the PKM highly accurate. This is achieved, among other things, through the use of CFRP rods, which are extremely stiff in their effective direction and have a low temperature coefficient.

In addition, the parallel kinematics module impresses with its powerful work. Despite the filigree structure, the available process force is on the level of a machine tool. The lightweight construction ensures extreme energy savings and thus works energy-efficiently. Fast and dynamic – the weight-optimised design enables extremely high dynamics. Last but not least, the PKM has the advantage of offering a large workspace. The linear crosshead axes and the bar lengths can be flexibly adapted to the requirements.

Powerful machining solutions for large working areas can be designed and built quickly and efficiently. It is a modular system that can be easily integrated into existing production lines and easily expanded into a multi-robot machine solution. This can also be added after the initial installation.

Quite simply: the various application possibilities and versatile configuration of the PKM. The system can be designed entirely according to your requirements. The high-speed configuration is optimised for low mass and fast movements with a nominal acceleration of 25m/s² and a process force of up to 6kN. The high-force configuration is optimised for high process forces with a process force of up to 15kN. The PKM closes the gaps between machine tools and serial arm robots – large components are thus no problem.

More info can be found here:

https://www.elha-robotic-automation.com/