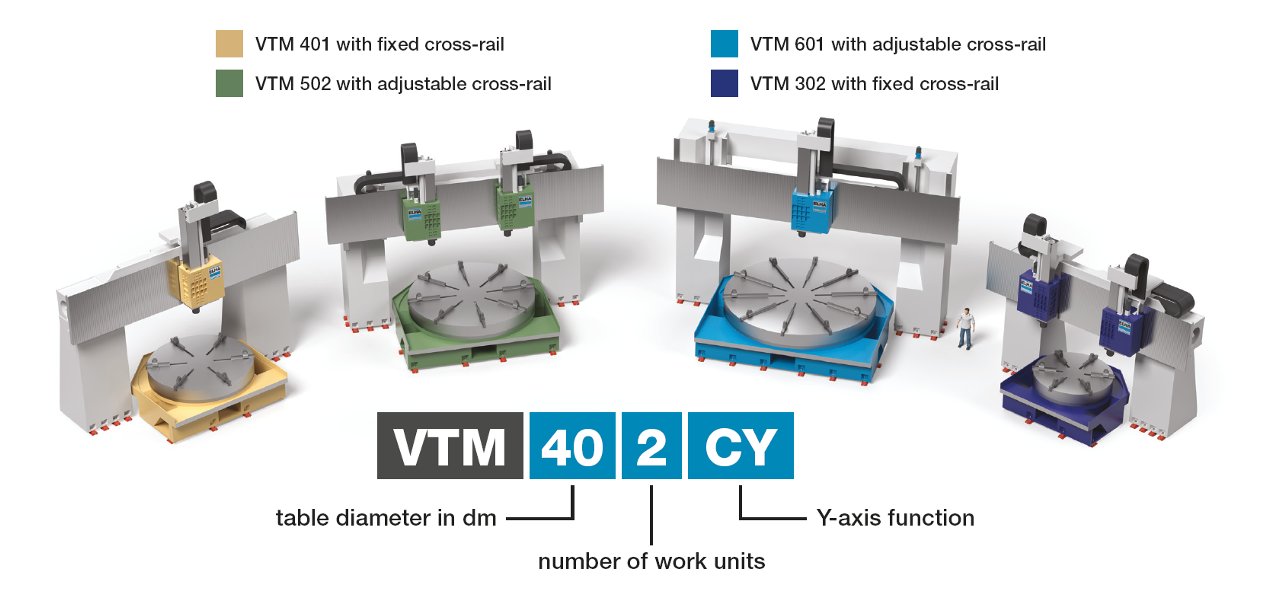

The VTM modules enable the configuration of the machine into a multi-functional turning-milling machining center for economical combined machining with a rotary table range from 2500 – 8000 mm and workpiece heights up to 5000 mm. All machines are equipped with two columns and one or two RAM work units. All sizes can be delivered with an adjustable cross-rail (W-axis). Additional advantages of this concept are its reliability and availability combined with cost advantages of proven and standardized machine components.

| 25 | 30 | 35 | 40 | 45 | 50 | 55 | 60 | 70 | 80 | ||

|---|---|---|---|---|---|---|---|---|---|---|---|

| table diameter | mm | 2.500 | 3.000 | 3.500 | 4.000 | 4.500 | 5.000 | 5.500 | 6.000 | 7.000 | 8.000 |

| swing diameter | mm | 2.800 | 3.300 | 3.800 | 4.300 | 4.800 | 5.500 | 6.000 | 6.500 | 7.500 | 8.500 |

| max. workpiece weight | t | 15 | 20 | 30 | 40 | 50 | 60 | 70 | 85 | 110 | 140 |

| max. turning height | mm | 5000 | |||||||||

| tool spindle drive | kW | 37 / 60 / 70 | |||||||||

| ram size | mm | 360×400 / 500×500 / 600×600 | |||||||||

| power table drive (S1) | kW | scalable | |||||||||

| table torque (S1) | kNm | scalable | |||||||||

| max. table speed | min-1 | scalable | |||||||||

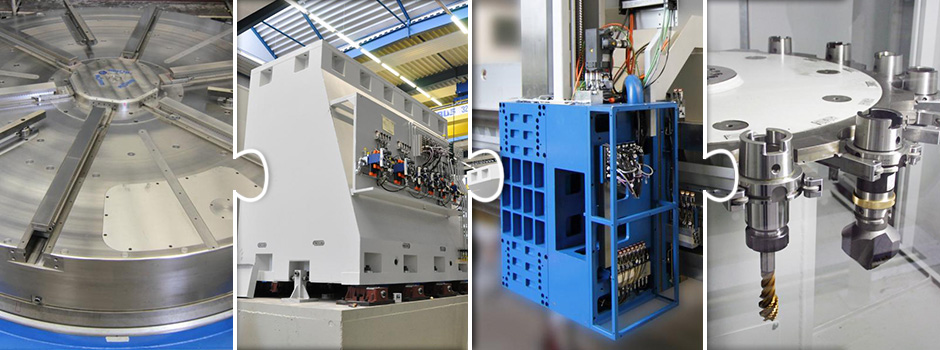

The RAM work units of the VTM series offer a range of innovative technologies for robust and accurate high precision machining as well as very flexible options for the different requirements in turning, drilling and milling operations.

| power / kW (S1) | RAM stroke / mm | |||||||

|---|---|---|---|---|---|---|---|---|

| RAM mm | 37 | 60 | 70 | 1250 | 1600 | 2000 | 2500 | 3000 |

| 360 x 400 | ■ | □ | ■ | □ | □ | |||

| 500 x 500 | ■ | □ | ■ | □ | □ | □ | ||

| 600 x 600 | ■ | □ | □ | ■ | □ | □ | □ | |

Next to standard magazines for tools and interchangeable heads ELHA offers individual solutions for your manufacturing needs in a variety of sizes. Additionally a wide range of compatible interchangeable heads is available for various machining applications.